Technical details

| Number of spindles | 6 St. |

| Working width | 230 mm |

| Working height | 120 mm |

| Length of the planing table | 2500 mm |

| Feed motor | 4 kW |

| Feed speed | 5-30 m/min. |

| Control | Weinig PowerCom |

Videos

Aucun fichier vidéo disponibleAdditional information

Weinig Powermat 500 for window production

---------------------------------------------

Machine will be checked at our warehouse

Short summary:

---------------------------------------------

6 Spindles with 8,000 rpm and 7.5 KW

5 x HSK/Powerlock

Window package with glazing bead separation

Spindles axially and radially CNC controlled

right and upper spindles with common pneumatic timing for

Glazing bead cutting

Large control Powercom with touchscreen

Detailed description:

---------------------------------------------

Tool arrangement No. 018 for window production

Technical specifications:

---------------------------------------------

Working width 20 - 230 mm (at tool cutting circle 93 - 125 mm)

Working height 8 - 120 mm (at tool cutting circle 93 - 125 mm)

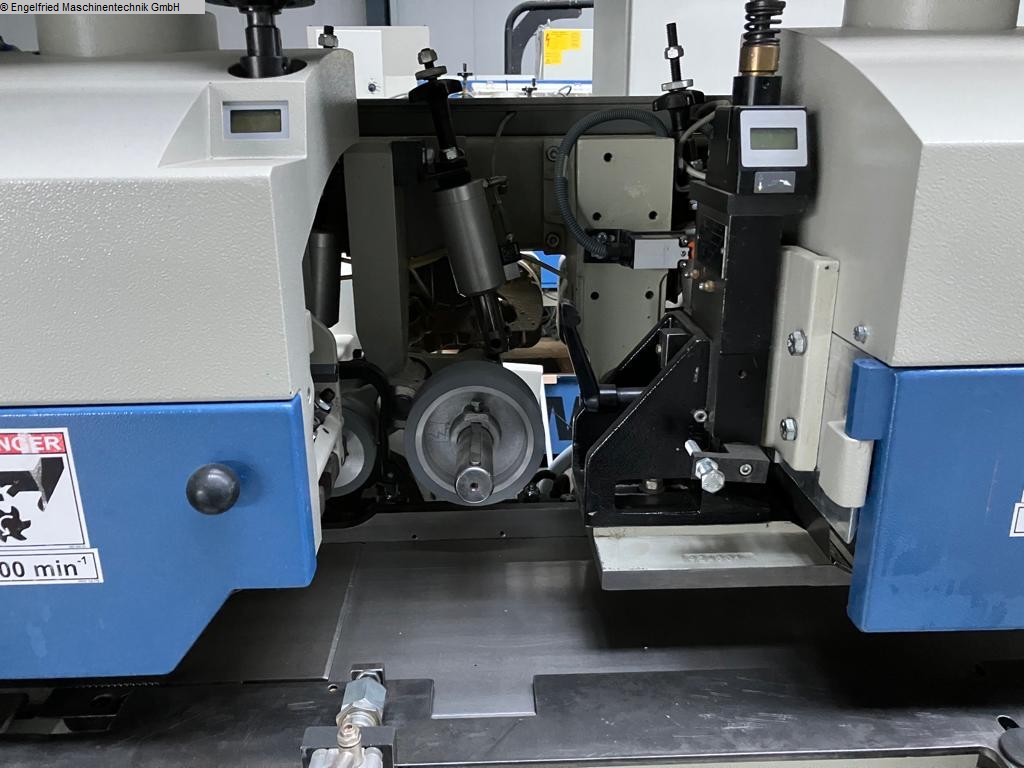

1. Tool holder

---------------------------------------------

First lower tool holder

Motor with brake 7.5 KW

Diameter: 40mm

Speed 8,000 rpm

including high-performance ball bearings

Tool flight circle 125 - 180 mm

In connection with PowerLock 93 - 180 mm

Axial adjustment range 17 mm

Hardened table insert in front of the 1st lower tool holder

2. POWERLOCK/HSK tool holder

---------------------------------------------

First right tool holder

Motor with brake 7.5 KW

Speed 8,000 rpm

including high-performance ball bearings

Tool flight circle 93 - 200 mm

Maximum throat depth 35 mm

Axial adjustment range for spindle 80 mm

Axial adjustment range for PowerLock 55 mm

Adjustment path radial

Min. tool diameter at stop level 93 mm

Max. tool diameter behind stop level 200 mm

Axially and radially CNC controlled

3. POWERLOCK/HSK tool holder

---------------------------------------------

First left tool holder

Motor with brake 7.5 KW

Speed 8,000 rpm

including high-performance ball bearings

Tool flight circle 93 - 200 mm

Tool cutting circle for straight cutter heads max. 163 mm

Maximum throat depth 35 mm

Axial adjustment range for spindle 80 mm

Axial adjustment range for PowerLock 55 mm

Pressure shoe in front of the left tool holder,

including 2 lateral pressure rollers, spring-loaded

Axially and radially CNC controlled

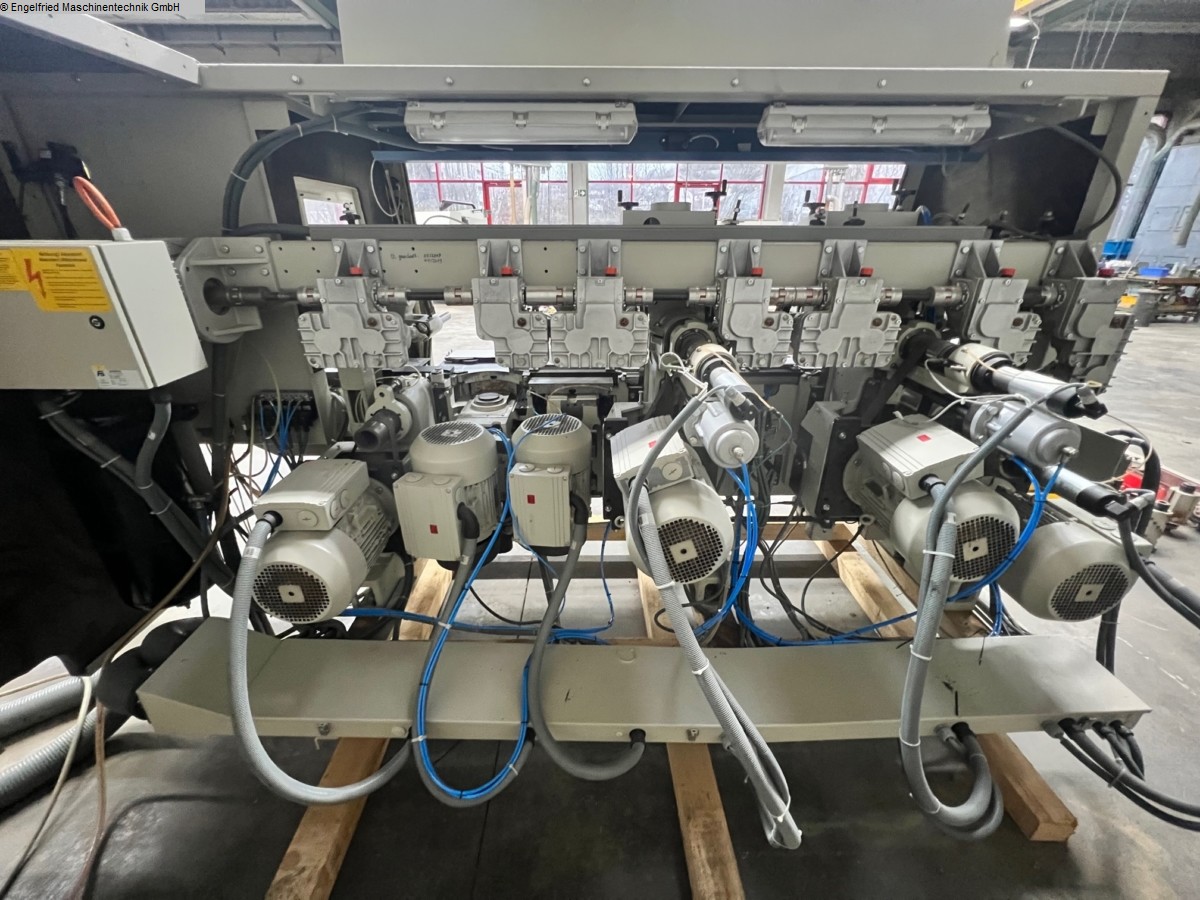

4. POWERLOCK/HSK tool holder

---------------------------------------------

First upper tool holder

Motor with brake 7.5 KW

Speed 8,000 rpm

including high-performance ball bearings

Tool flight circle 93 - 200 mm

Tool cutting circle for straight cutter heads max. 163 mm

Maximum throat depth 35 mm

Adjustment path axial 40 mm

Axially and radially CNC controlled

5. POWERLOCK/HSK tool holder

---------------------------------------------

Second upper tool holder

Motor with brake 7.5 KW

Speed 8,000 rpm

including high-performance ball bearings

Tool flight circle 93 - 200 mm

Tool cutting circle for straight cutter heads max. 163 mm

Maximum throat depth 35 mm

Adjustment path axial 40 mm

Axially and radially CNC controlled

6. POWERLOCK/HSK tool holder

---------------------------------------------

Second lower tool holder

Motor with brake 7.5 KW

Speed 8,000 rpm

including high-performance ball bearings

Tool flight circle 93 - 225 mm

Maximum throat depth 15 mm

Adjustment path axial 40 mm

Adjustment path radial

Min. tool diameter to table level 93 mm

Max. tool diameter 6 mm under table level 225 mm

Axially and radially CNC controlled

Stop on the 2nd lower spindle for round rod milling cutters excepted

Additional short table tops before and after the lower spindle

for profiling work with large valley depths

All tool holders with high concentricity.

Lubrication points for the axial tool holder movement.

feed system

---------------------------------------------

Frequency-controlled feed, 5 - 30 m/min.

infinitely variable with brake 4 KW

Feed roller in front of the 1st lower tool

pneumatic high-low controlled

Durofer pointed tooth rollers (Weinig patent)

with depth limiter and self-cleaning

Adjustment path of the feed rollers opposite

left tool holder, axial 35 mm

Reduction of the center distances between the feed pendulums to 400 mm included

additional feed roller (diameter 95 mm and 140 mm)

and shortened roller spacing

machine electrics

---------------------------------------------

Operating voltage 400 volts

(Voltage range 380 x 420 volts), 50 Hz

Electrical design according to DIN VDE 0113,

electrical equipment of industrial machines

EN60204, IEC-204-1. Other electrical regulations

are not included.

Control cabinet (with control panel) separately from

Machine, distance control cabinet-machine: 2.5 m

Machine stand, table and stops

---------------------------------------------

Dressing table 2.5 m long (incl. jointing ruler)

Manual Waxilit pump for table resin removal.

A driven rubber roller in the outfeed table,

50 mm wide, air cushion system in the machine table,

1 track controlled via pendulum shafts.

pressure rollers and guides

---------------------------------------------

Pressure rollers from above, spring-loaded

Lateral pressure roller on the infeed table, spring-loaded

Additional discharge for round bar production after the second upper spindle

machine operation

Window package 1 Powermat 500/018

---------------------------------------------

1. Right spindle pneumatically clocked axially (55 mm)

1st and 2nd upper spindle pneumatically clocked axially by selector switch

(40 mm), saw blade max. 180 mm.

Discharge after the 1st upper spindle axially manually adjustable (at 0,12,0,18)

Joint control of the right and top

Spindle (axial stroke) and the glazing bead discharge

via manual selector switch in control panel

Glazing bead removal after (last) upper one

Spindle pneumatic forwards/backwards.

Additional non-powered feed pendulum

after the last upper spindle to hold down

the square bar

Stops to the right spindle at 35 mm

left out for cutting out square strips

Machine prepared for electrical linking

for parts - return system including emergency stop chain

parts monitoring

Window package 2 Powermat 500/018

---------------------------------------------

PowerCom, touch screen

Guide ruler to the left spindle 8 mm thick, pneumatic

controlled to timber width. standard rulers are omitted,

The standard working width of the complete machine is reduced

from 230mm to 200mm. For last production manually

set to wood width

Motorized axle adjustments:

5 radial motorized adjustment and positioning of the tool holders

in connection with PowerCom, spindle no. 2,3,4,5,6

5 axial motorized adjustment and positioning of the tool holders

in connection with PowerCom, spindle no. 2,3,4,5,6

Motorized axis adjustment and positioning of the feed up/down

in connection with the PowerCOM

Central location of greasing points at the front of the machine

PowerCom control:

---------------------------------------------

Profile and tool data management software

Setting values can be calculated or saved.

These are shown on the electronic double displays.

Touchscreen - function for graphically supported operation

10,000 profile and tool storage locations each

Integrated network card for connection to OptiContro or other PCs

USB connection for manual data transfer

safety and soundproofing

---------------------------------------------

Safety full fairing

Easily foldable safety hood with window covers

the entire work area and protects against mechanical

Driven.

When the safety hood is raised, tool holders

and feed switched off automatically.

With the CE version, the safety cover can be opened during

automatic mode is not possible.

Electromagnetic locking of the safety hood

(only after the tools have come to a standstill, approx. 15 seconds,

the hood can be opened)

The machine comes with CE mark and associated

EC declaration of conformity supplied.

Two interior lights in the safety hood

For ripping work, e.g. sawing and multiple profiling,

you need suitable protective devices.

Option: existing PowerLock spindles and tools

Option: Outfeed conveyor belt with discharge for glazing bead

(technical data according to the manufacturer - without guarantee!)

---------------------------------------------

Machine will be checked at our warehouse

Short summary:

---------------------------------------------

6 Spindles with 8,000 rpm and 7.5 KW

5 x HSK/Powerlock

Window package with glazing bead separation

Spindles axially and radially CNC controlled

right and upper spindles with common pneumatic timing for

Glazing bead cutting

Large control Powercom with touchscreen

Detailed description:

---------------------------------------------

Tool arrangement No. 018 for window production

Technical specifications:

---------------------------------------------

Working width 20 - 230 mm (at tool cutting circle 93 - 125 mm)

Working height 8 - 120 mm (at tool cutting circle 93 - 125 mm)

1. Tool holder

---------------------------------------------

First lower tool holder

Motor with brake 7.5 KW

Diameter: 40mm

Speed 8,000 rpm

including high-performance ball bearings

Tool flight circle 125 - 180 mm

In connection with PowerLock 93 - 180 mm

Axial adjustment range 17 mm

Hardened table insert in front of the 1st lower tool holder

2. POWERLOCK/HSK tool holder

---------------------------------------------

First right tool holder

Motor with brake 7.5 KW

Speed 8,000 rpm

including high-performance ball bearings

Tool flight circle 93 - 200 mm

Maximum throat depth 35 mm

Axial adjustment range for spindle 80 mm

Axial adjustment range for PowerLock 55 mm

Adjustment path radial

Min. tool diameter at stop level 93 mm

Max. tool diameter behind stop level 200 mm

Axially and radially CNC controlled

3. POWERLOCK/HSK tool holder

---------------------------------------------

First left tool holder

Motor with brake 7.5 KW

Speed 8,000 rpm

including high-performance ball bearings

Tool flight circle 93 - 200 mm

Tool cutting circle for straight cutter heads max. 163 mm

Maximum throat depth 35 mm

Axial adjustment range for spindle 80 mm

Axial adjustment range for PowerLock 55 mm

Pressure shoe in front of the left tool holder,

including 2 lateral pressure rollers, spring-loaded

Axially and radially CNC controlled

4. POWERLOCK/HSK tool holder

---------------------------------------------

First upper tool holder

Motor with brake 7.5 KW

Speed 8,000 rpm

including high-performance ball bearings

Tool flight circle 93 - 200 mm

Tool cutting circle for straight cutter heads max. 163 mm

Maximum throat depth 35 mm

Adjustment path axial 40 mm

Axially and radially CNC controlled

5. POWERLOCK/HSK tool holder

---------------------------------------------

Second upper tool holder

Motor with brake 7.5 KW

Speed 8,000 rpm

including high-performance ball bearings

Tool flight circle 93 - 200 mm

Tool cutting circle for straight cutter heads max. 163 mm

Maximum throat depth 35 mm

Adjustment path axial 40 mm

Axially and radially CNC controlled

6. POWERLOCK/HSK tool holder

---------------------------------------------

Second lower tool holder

Motor with brake 7.5 KW

Speed 8,000 rpm

including high-performance ball bearings

Tool flight circle 93 - 225 mm

Maximum throat depth 15 mm

Adjustment path axial 40 mm

Adjustment path radial

Min. tool diameter to table level 93 mm

Max. tool diameter 6 mm under table level 225 mm

Axially and radially CNC controlled

Stop on the 2nd lower spindle for round rod milling cutters excepted

Additional short table tops before and after the lower spindle

for profiling work with large valley depths

All tool holders with high concentricity.

Lubrication points for the axial tool holder movement.

feed system

---------------------------------------------

Frequency-controlled feed, 5 - 30 m/min.

infinitely variable with brake 4 KW

Feed roller in front of the 1st lower tool

pneumatic high-low controlled

Durofer pointed tooth rollers (Weinig patent)

with depth limiter and self-cleaning

Adjustment path of the feed rollers opposite

left tool holder, axial 35 mm

Reduction of the center distances between the feed pendulums to 400 mm included

additional feed roller (diameter 95 mm and 140 mm)

and shortened roller spacing

machine electrics

---------------------------------------------

Operating voltage 400 volts

(Voltage range 380 x 420 volts), 50 Hz

Electrical design according to DIN VDE 0113,

electrical equipment of industrial machines

EN60204, IEC-204-1. Other electrical regulations

are not included.

Control cabinet (with control panel) separately from

Machine, distance control cabinet-machine: 2.5 m

Machine stand, table and stops

---------------------------------------------

Dressing table 2.5 m long (incl. jointing ruler)

Manual Waxilit pump for table resin removal.

A driven rubber roller in the outfeed table,

50 mm wide, air cushion system in the machine table,

1 track controlled via pendulum shafts.

pressure rollers and guides

---------------------------------------------

Pressure rollers from above, spring-loaded

Lateral pressure roller on the infeed table, spring-loaded

Additional discharge for round bar production after the second upper spindle

machine operation

Window package 1 Powermat 500/018

---------------------------------------------

1. Right spindle pneumatically clocked axially (55 mm)

1st and 2nd upper spindle pneumatically clocked axially by selector switch

(40 mm), saw blade max. 180 mm.

Discharge after the 1st upper spindle axially manually adjustable (at 0,12,0,18)

Joint control of the right and top

Spindle (axial stroke) and the glazing bead discharge

via manual selector switch in control panel

Glazing bead removal after (last) upper one

Spindle pneumatic forwards/backwards.

Additional non-powered feed pendulum

after the last upper spindle to hold down

the square bar

Stops to the right spindle at 35 mm

left out for cutting out square strips

Machine prepared for electrical linking

for parts - return system including emergency stop chain

parts monitoring

Window package 2 Powermat 500/018

---------------------------------------------

PowerCom, touch screen

Guide ruler to the left spindle 8 mm thick, pneumatic

controlled to timber width. standard rulers are omitted,

The standard working width of the complete machine is reduced

from 230mm to 200mm. For last production manually

set to wood width

Motorized axle adjustments:

5 radial motorized adjustment and positioning of the tool holders

in connection with PowerCom, spindle no. 2,3,4,5,6

5 axial motorized adjustment and positioning of the tool holders

in connection with PowerCom, spindle no. 2,3,4,5,6

Motorized axis adjustment and positioning of the feed up/down

in connection with the PowerCOM

Central location of greasing points at the front of the machine

PowerCom control:

---------------------------------------------

Profile and tool data management software

Setting values can be calculated or saved.

These are shown on the electronic double displays.

Touchscreen - function for graphically supported operation

10,000 profile and tool storage locations each

Integrated network card for connection to OptiContro or other PCs

USB connection for manual data transfer

safety and soundproofing

---------------------------------------------

Safety full fairing

Easily foldable safety hood with window covers

the entire work area and protects against mechanical

Driven.

When the safety hood is raised, tool holders

and feed switched off automatically.

With the CE version, the safety cover can be opened during

automatic mode is not possible.

Electromagnetic locking of the safety hood

(only after the tools have come to a standstill, approx. 15 seconds,

the hood can be opened)

The machine comes with CE mark and associated

EC declaration of conformity supplied.

Two interior lights in the safety hood

For ripping work, e.g. sawing and multiple profiling,

you need suitable protective devices.

Option: existing PowerLock spindles and tools

Option: Outfeed conveyor belt with discharge for glazing bead

(technical data according to the manufacturer - without guarantee!)

On this page you will find a an offer on a used 4 side moulder of type Powermat 500 Fenster of the company WEINIG with year of construction gebraucht and with stock no.: 1305-2712. The machine is manufactured by the company Engelfried Maschinentechnik GmbH from 73432 Aalen offered. The delivery time / delivery status for this machine is: immediately For more information, please refer to the details listed.

Machine

4 side moulder