Machine data

Document

Aucun autre document disponibleTechnical details

| Number of spindles | 6 St. |

| Working width | 230 mm |

| Working height | 120 mm |

| Length of the planing table | 2500 mm |

| Feed motor | 4 kW |

| Feed speed | 5-30 m/min. |

Videos

Aucun fichier vidéo disponibleAdditional information

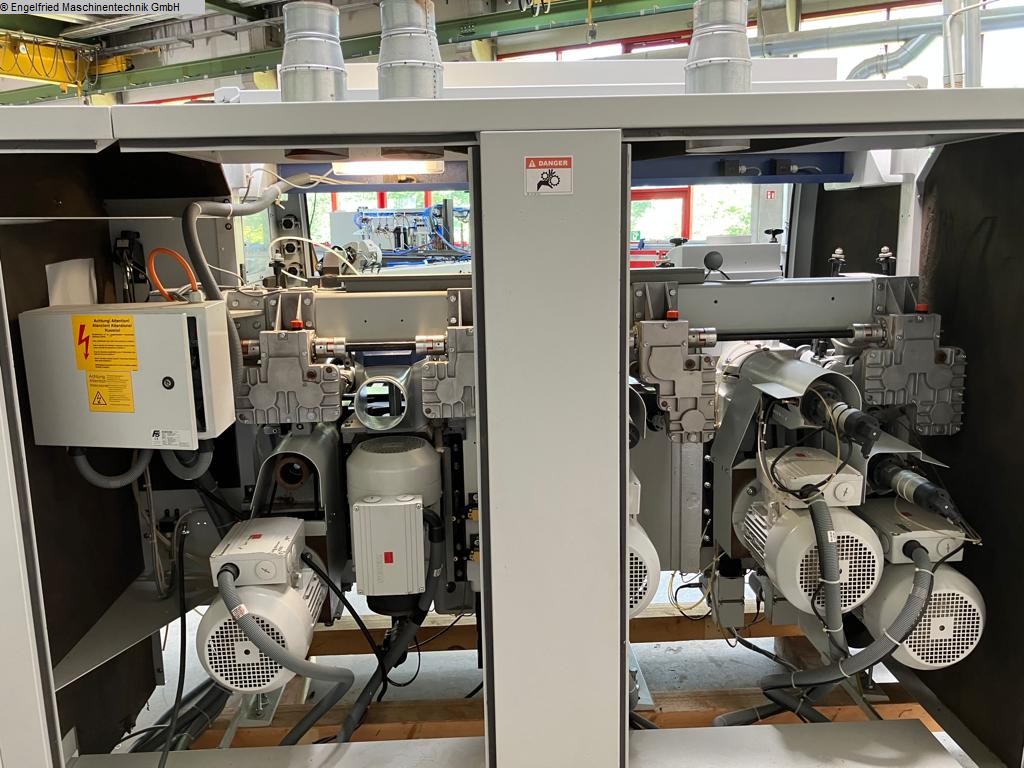

Weinig Powermat 400 with HSK/Powerlock, axial/radial CNC controlled

-----------------------------------------------------------------------

Short summary:

-----------------------------------------------------------------------

6 spindles with 8,000 rpm

5 x HSK/Powerlock

Axial and radial CNC adjustment of the spindles via control

CNC - controlled adjustment and positioning of the feed

Detailed description:

-----------------------------------------------------------------------

Technical specifications:

Working width: 20-230 mm

Working height: 8-120 mm

Number of spindles: 6

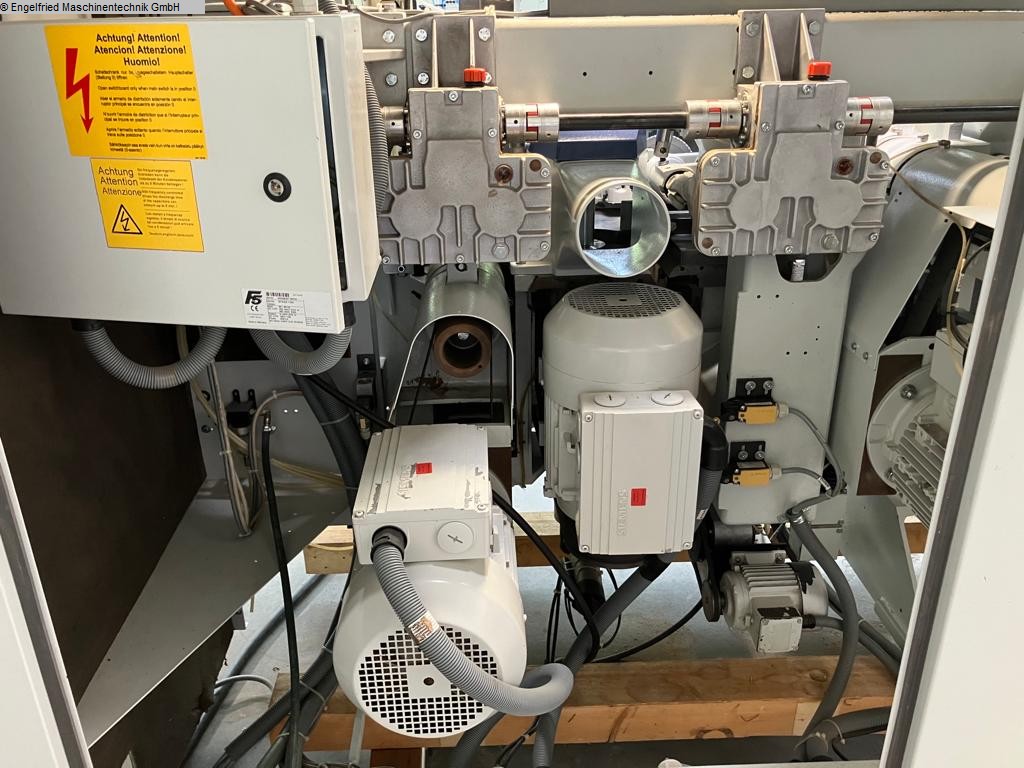

1. Tool holder - below

------------------------------------------------

Motor with brake: 5.5 kW

Spindle diameter: 40mm

Speed: 6,000 rpm

Tool flight circle: 93 - 160 mm

Axial adjustment range: 5 mm

Rebating device

MarathonCoatin for table insert in front of 1st lower tool holder

2. Tool holder - PowerLock - right

------------------------------------------------

Motor with brake: 11.0 kW

Common motor with left tool holder

Speed ??including high-performance ball bearing: 8,000 rpm

Tool flight circle 40 mm below table level: 93 - 200 mm

Tool flight circle 55 mm below table level: 93 - 180 mm

Tool cutting circle for straight cutter heads max. 163 mm

Max. tool diameter behind stop level: 180 mm

Max throat depth: 35 mm

Axial adjustment range: 55 mm

Spindle axially and radially CNC controlled

3. Tool holder - PowerLock - left

------------------------------------------------

Motor with brake: Common motor with the 2nd spindle

Speed ??including high-performance ball bearing: 8,000 rpm

Tool flight circle 40 mm below table level: 93 - 200 mm

Tool flight circle 55 mm below table level: 93 - 180 mm

Tool cutting circle for straight cutter heads max. 163 mm

Max throat depth: 35 mm

Axial adjustment range: 55 mm

Spindle axially and radially CNC controlled

4. Tool holder - PowerLock - above

------------------------------------------------

Motor with brake: 7.5 kW

Speed ??including high-performance ball bearing: 8,000 rpm

Tool flight circle: 93 - 200 mm

Tool cutting circle for straight cutter heads max.: 180 mm

Max throat depth: 35 mm

Axial adjustment range: 40 mm

Divided pressure shoe in front of the upper tool holder, on tool flight circle

adjustable and pivoting away from the tool, spring-loaded.

Radial CNC-controlled spindle

5. Tool holder - PowerLock - above

------------------------------------------------

Motor with brake: 7.5 kW

Speed ??including high-performance ball bearing: 8,000 rpm

Tool flight circle: 93 - 200 mm

Tool cutting circle for straight cutter heads max. : 180 mm

Max throat depth: 35 mm

Axial adjustment range: 40 mm

Divided pressure shoe in front of the upper tool holder, on tool flight circle

adjustable and pivoting away from the tool, spring-loaded.

Spindle axially and radially CNC controlled

6. Tool holder - PowerLock - below

------------------------------------------------

Motor with brake: 7.5 kW

Speed ??including high-performance ball bearing: 8,000 rpm

Tool flight circle: 93 - 200 mm

Max throat depth: 15 mm

Axial adjustment range: 35 mm

Radial CNC-controlled spindle

feed system

------------------------------------------------

Frequency-controlled feed, infinitely adjustable with brake: 4 kW, 5 - 30 m/min

Feed roller in front of the 1st lower tool pneumatically controlled up/down.

Durofer toothed rollers (Weinig patent) with depth limiter and self-cleaning.

Adjustment range of the feed rollers compared to the left tool holder, axial 35

mm

Reduction of the feed roller distances to 510 mm,

including additional feed rollers after the upper tool holders

(diameter 140 mm) and shortened roller spacing, roller width 50 mm

machine electrics

------------------------------------------------

Operating voltage 400 V (voltage range 380 - 420 volts), 50 Hz.

Electrical design according to DIN VDE 0113, electrical equipment from

Industrial machinery EN60204, IEC-204-1. Other electrical regulations are

not considered.

Machine stands, tables and stops

------------------------------------------------

Dressing table: 2500 mm long (including joint ruler)

Manual Waxilit pump for table resin removal

A driven rubber roller in the outfeed table - 50 mm wide

A driven, hardened steel roller in the machine table, spring-loaded - 150 mm

broad

pressure elements and guides

------------------------------------------------

A lateral pressure roller in front of the left tool holder, moving and

sprung.

Lateral pressure roller on the infeed table, spring-loaded

machine operation

------------------------------------------------

Control: memory function

For saving the setting values ??of profiles.

Tool holder axes with electronic digital displays.

Function:

Saving the setting values ??of the manufactured profile at the push of a button

under a profile number.

If the profile number is selected again, the electronic double displays show

the setting values.

By manually adjusting the tool holders, the displays in

matched. 99 memory locations.

Basic equipment for installing the CNC-controlled adjustment

and positioning

3 x axial CNC-controlled adjustment and positioning of the tool holders

in conjunction with the memory function for tool holders 2,3,5

5 x radial CNC-controlled adjustment and positioning of the tool holders

in conjunction with the memory function for tool holders 2,3,4,5,6

CNC - controlled adjustment and positioning of the feed

high/low in connection with the memory function

Lubrication points for the axial tool holder adjustment.

Central location of greasing points at the front of the machine.

safety and soundproofing

------------------------------------------------

Full security fairing

Electromagnetic locking of the safety cover

interior light

Machine without machining tools

(Technical information according to the manufacturer - without guarantee!)

-----------------------------------------------------------------------

Short summary:

-----------------------------------------------------------------------

6 spindles with 8,000 rpm

5 x HSK/Powerlock

Axial and radial CNC adjustment of the spindles via control

CNC - controlled adjustment and positioning of the feed

Detailed description:

-----------------------------------------------------------------------

Technical specifications:

Working width: 20-230 mm

Working height: 8-120 mm

Number of spindles: 6

1. Tool holder - below

------------------------------------------------

Motor with brake: 5.5 kW

Spindle diameter: 40mm

Speed: 6,000 rpm

Tool flight circle: 93 - 160 mm

Axial adjustment range: 5 mm

Rebating device

MarathonCoatin for table insert in front of 1st lower tool holder

2. Tool holder - PowerLock - right

------------------------------------------------

Motor with brake: 11.0 kW

Common motor with left tool holder

Speed ??including high-performance ball bearing: 8,000 rpm

Tool flight circle 40 mm below table level: 93 - 200 mm

Tool flight circle 55 mm below table level: 93 - 180 mm

Tool cutting circle for straight cutter heads max. 163 mm

Max. tool diameter behind stop level: 180 mm

Max throat depth: 35 mm

Axial adjustment range: 55 mm

Spindle axially and radially CNC controlled

3. Tool holder - PowerLock - left

------------------------------------------------

Motor with brake: Common motor with the 2nd spindle

Speed ??including high-performance ball bearing: 8,000 rpm

Tool flight circle 40 mm below table level: 93 - 200 mm

Tool flight circle 55 mm below table level: 93 - 180 mm

Tool cutting circle for straight cutter heads max. 163 mm

Max throat depth: 35 mm

Axial adjustment range: 55 mm

Spindle axially and radially CNC controlled

4. Tool holder - PowerLock - above

------------------------------------------------

Motor with brake: 7.5 kW

Speed ??including high-performance ball bearing: 8,000 rpm

Tool flight circle: 93 - 200 mm

Tool cutting circle for straight cutter heads max.: 180 mm

Max throat depth: 35 mm

Axial adjustment range: 40 mm

Divided pressure shoe in front of the upper tool holder, on tool flight circle

adjustable and pivoting away from the tool, spring-loaded.

Radial CNC-controlled spindle

5. Tool holder - PowerLock - above

------------------------------------------------

Motor with brake: 7.5 kW

Speed ??including high-performance ball bearing: 8,000 rpm

Tool flight circle: 93 - 200 mm

Tool cutting circle for straight cutter heads max. : 180 mm

Max throat depth: 35 mm

Axial adjustment range: 40 mm

Divided pressure shoe in front of the upper tool holder, on tool flight circle

adjustable and pivoting away from the tool, spring-loaded.

Spindle axially and radially CNC controlled

6. Tool holder - PowerLock - below

------------------------------------------------

Motor with brake: 7.5 kW

Speed ??including high-performance ball bearing: 8,000 rpm

Tool flight circle: 93 - 200 mm

Max throat depth: 15 mm

Axial adjustment range: 35 mm

Radial CNC-controlled spindle

feed system

------------------------------------------------

Frequency-controlled feed, infinitely adjustable with brake: 4 kW, 5 - 30 m/min

Feed roller in front of the 1st lower tool pneumatically controlled up/down.

Durofer toothed rollers (Weinig patent) with depth limiter and self-cleaning.

Adjustment range of the feed rollers compared to the left tool holder, axial 35

mm

Reduction of the feed roller distances to 510 mm,

including additional feed rollers after the upper tool holders

(diameter 140 mm) and shortened roller spacing, roller width 50 mm

machine electrics

------------------------------------------------

Operating voltage 400 V (voltage range 380 - 420 volts), 50 Hz.

Electrical design according to DIN VDE 0113, electrical equipment from

Industrial machinery EN60204, IEC-204-1. Other electrical regulations are

not considered.

Machine stands, tables and stops

------------------------------------------------

Dressing table: 2500 mm long (including joint ruler)

Manual Waxilit pump for table resin removal

A driven rubber roller in the outfeed table - 50 mm wide

A driven, hardened steel roller in the machine table, spring-loaded - 150 mm

broad

pressure elements and guides

------------------------------------------------

A lateral pressure roller in front of the left tool holder, moving and

sprung.

Lateral pressure roller on the infeed table, spring-loaded

machine operation

------------------------------------------------

Control: memory function

For saving the setting values ??of profiles.

Tool holder axes with electronic digital displays.

Function:

Saving the setting values ??of the manufactured profile at the push of a button

under a profile number.

If the profile number is selected again, the electronic double displays show

the setting values.

By manually adjusting the tool holders, the displays in

matched. 99 memory locations.

Basic equipment for installing the CNC-controlled adjustment

and positioning

3 x axial CNC-controlled adjustment and positioning of the tool holders

in conjunction with the memory function for tool holders 2,3,5

5 x radial CNC-controlled adjustment and positioning of the tool holders

in conjunction with the memory function for tool holders 2,3,4,5,6

CNC - controlled adjustment and positioning of the feed

high/low in connection with the memory function

Lubrication points for the axial tool holder adjustment.

Central location of greasing points at the front of the machine.

safety and soundproofing

------------------------------------------------

Full security fairing

Electromagnetic locking of the safety cover

interior light

Machine without machining tools

(Technical information according to the manufacturer - without guarantee!)

On this page you will find a an offer on a used 4 side moulder of type Powermat 400 CNC_Powerlock of the company WEINIG with year of construction gebraucht and with stock no.: 1305-2692. The machine is manufactured by the company Engelfried Maschinentechnik GmbH from 73432 Aalen offered. The delivery time / delivery status for this machine is: immediately For more information, please refer to the details listed.

Documents et vidéos

Aucun autre document disponible

Aucun fichier vidéo disponible

Machine

4 side moulder