CNC processing centre windows & doors

Machinelist: CNC processing centre windows & doors

CNC processing centre windows & doors

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5602 · CNC processing centre windows & doors

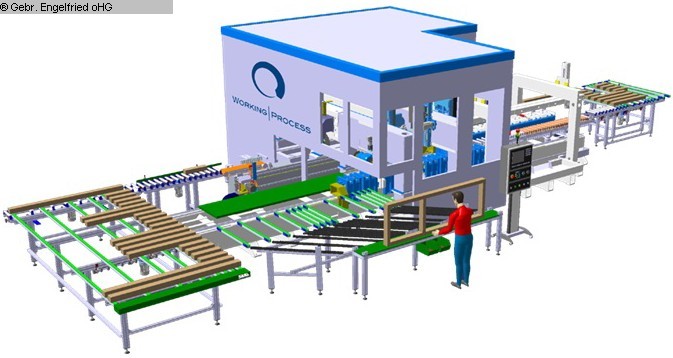

WORKING PROCESS - Fensteranlage -Video- - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6360 · CNC processing centre windows & doors

WORKING PROCESS - Logos Life Evo XS Video - - neu - Siemens 840d

Technical details

Working Process Logos Life Evo XS 2345 ------------------------------- Vollautomatisches CNC-Fensterfertigungsanlage mit automatischer Be- und Entladung. 2 Portale mit 3 Frässpindeln mit 4- und 5-Achstechnologie CNC-gesteuerter Manipulator für Werkstückpositionierung mit 16 Stück Doppelzangen 8 Stück komplett unabhängige Werkstückspanner für höchste Felxibilität und Produktivität 128 Werkzeugplätze NEU: Working Process baut nun auch 1-spindlige Anlagen mit bewährter Technologie für kleinere Betriebe! Nebenstehend finde Sie aktuelle Videos dieser Baureihe.

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6511 · CNC processing centre windows & doors

MASTERWOOD - 4 Win mit Beladung - Video - - - neu -

Technical details

CNC machining center MASTERWOOD 4 WIN with automatic loading and unloading -------------------------------------------- Specially designed for a rational and flexible wooden window u. door production HIGHLIGHTS: - Various tool magazines for optimal tooling - Simultaneous feeding with up to 6 workpieces - patented clamping system for optimum machining of workpieces - CNC controlled work table with automatic positioning of the beams and Stretcher - Automatic reclamping for changing between external and internal profiling - INTEGRATED windowing software, i. Machine does not have to (but can Of course) be controlled from the office with external industry software. - powerful engine with 19.2 kW HSK-63 E - Loading and unloading conveyor Ask for a quote and see for yourself unbeatable value for money! VIDEO from the machine attached! At the side you will find the techn. Description of the machine as a PDF document. We would be happy to make your used machine one take reasonable price in payment! (technical information according to the manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6520 · CNC processing centre windows & doors

MASTERWOOD - Project385 Innenausbau,Fenster - - neu - Beckhoff CNC

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6428 · CNC processing centre windows & doors

MASTERWOOD - Project 385 WL,Allround, Video - - neu - Beckhoff CNC

Technical details

CNC machining center Masterwood Project 385 WL, NEUMASCHINE The all-rounder for Windows, round arches and doors interior Post and beam 5-axis machining of all kinds Detailed description in the adjacent PDF file! HIGHLIGHTS: - Working range: X = 5150 mm; Y = 1500 mm; Z = 200 mm - 1 pc. 5-axis high-performance spindle, 16 kW, double bearing with HSK 63 F recording - fixed drill head with 19 spindles with 7 individually retrievable vertical spindles X-direction with 6 individually retrievable vertical spindles Y-direction with 2 double horizontal spindles X-direction and 1 double horizontal boring spindle in the Y direction Saw unit integrated in drill head - Carousel tool changer with 22 places and 102 mm grid spacing - Carousel tool changer with 16 places and 102 mm grid spacing - linear 4-fold tool magazine - Special clamps for straight window and door parts - special clamps for round window and door elements - 24 pcs. Vacuum clamps for internal installation - Vacuum pump - Chip conveyor belt - extensive design software for interior design, panel processing as well as f. Windows and doors: Masterwork: 2D-Wop for standard application panel processing / interior fitting with Additional function Lamello connection Master 3D Level 2: for more complex edits, optionally also expandable for 5-axis fully interpolating MasterWindow: Integrated window and door design software i.e. Machine does not have to (but of course) with external industry software be controlled. VIDEO shows production of 4 sash parts in one clamping Complete machining including glazing bead production. Corner joint hybrid. Of course, all common corner joints on the machine producible. OTHER OPTIONS ON REQUEST! We are also happy to offer you suitable tools for the machine. (Techn.According to the manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2703 · CNC processing centre windows & doors

MASTERWOOD - 4 Win,Fenster,Tueren - Video - - - 2023 - Beckhoff

Technical details

CNC machining center MASTERWOOD 4 WIN --------------------------------------------------------- STOCK MACHINE: Immediately available!!!!! Specially designed for a rational and flexible wooden window u. door production HIGHLIGHTS: - Different tool magazines for optimal tool loading - Simultaneous loading of 4 workpieces - Patented clamping system for optimal processing of the workpieces - CNC controlled work table with automatic positioning of beams and Stretcher - Automatic re-clamping for changing between external and internal profiling - INTEGRATED window construction software, i.e. the machine does not have to (but can of course) can be controlled from the office with external industry software. - strong motor with 19.2 kW HSK-63 E Please note that this stock machine is with us in Oberkochen and is already equipped with many useful options. Tools available at short notice on request! Request an offer and see for yourself unbeatable value for money! VIDEO of the machine on request! Below you will find the technical Description of the machine as a PDF document. We would be happy to sell your used machine to a pay a reasonable price! Suitable stationary or mobile suction on request! (see e.g. #5674 NESTRO NE 300) Suitable compressor on request! (#5997 Kaeser Aircenter SM 15) (technical information according to the manufacturer - without guarantee!)

Datasheet

Request / Contact