Plants complete

Machinelist: Plants, complete

Plants, complete

- MEB Maschinenhandel GmbH

- Schwalbenweg 4

- 30826 Garbsen

- Deutschland

-

(0)5031 9394-634

-

info@meb-maschinenhandel.de

www.meb-maschinenhandel.de

#2037-G211102 · Plants, complete

HAN S LASER - OP Maskenanlage - - ca. 2021 -

Technical details

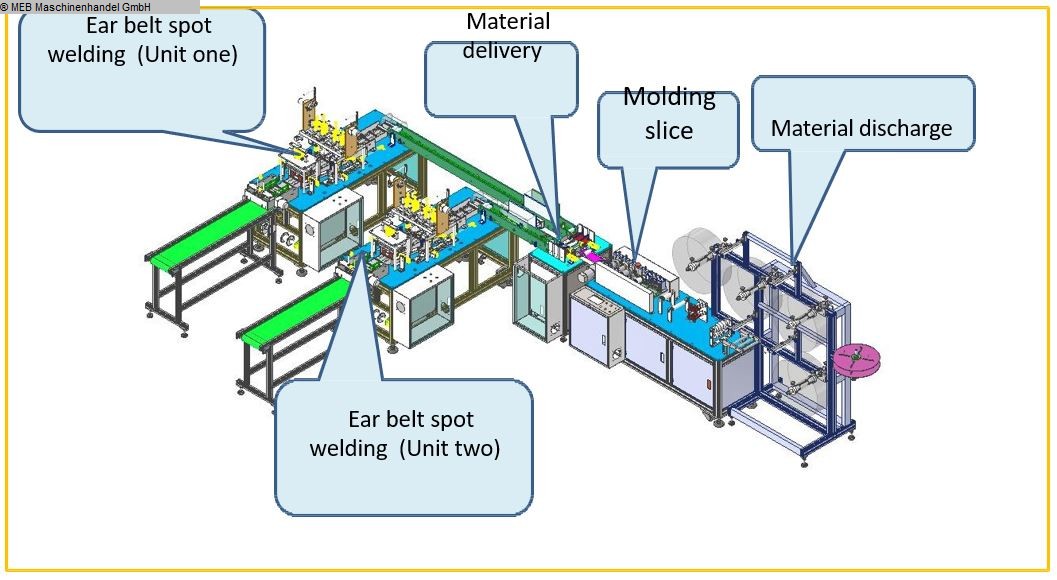

Condition: used - as good as new unit is still completely packed Specification: Medical surgical mask system complete Consisting of: - See sketches in the attachment Summary of the equipment: This machine is mainly used for automatic forming of plane mask: the whole roll of cloth is driven by roller after being unrolled, and the cloth is folded and wrapped automatically. The nose bridge strip is rolled up for traction and unrolled. After cutting with a fixed length, it is imported into the edge cloth. The two sides are welded to the seal by ultrasonic welding. The mask was transported to two mask ear belt welding stations by the assembly line, and the mask was finally formed by ultrasonic welding. After the mask is made, it is transported to the flat belt line through the assembly line for collection. - CE certified is available - Space requirement L/W/H approx.: 6,850 x 3,600 x 1,900 mm - Weight approx.: 5,000 kg - Paint finish: RAL 9003 - Voltage: 220V AC, 50 Hz - Total power approx.: 9 kW

- MEB Maschinenhandel GmbH

- Schwalbenweg 4

- 30826 Garbsen

- Deutschland

-

(0)5031 9394-634

-

info@meb-maschinenhandel.de

www.meb-maschinenhandel.de

#2037-G211101 · Plants, complete

HAN S LASER - FFP 2 Maskenanlage N95 - - ca. 2019 -

Technical details

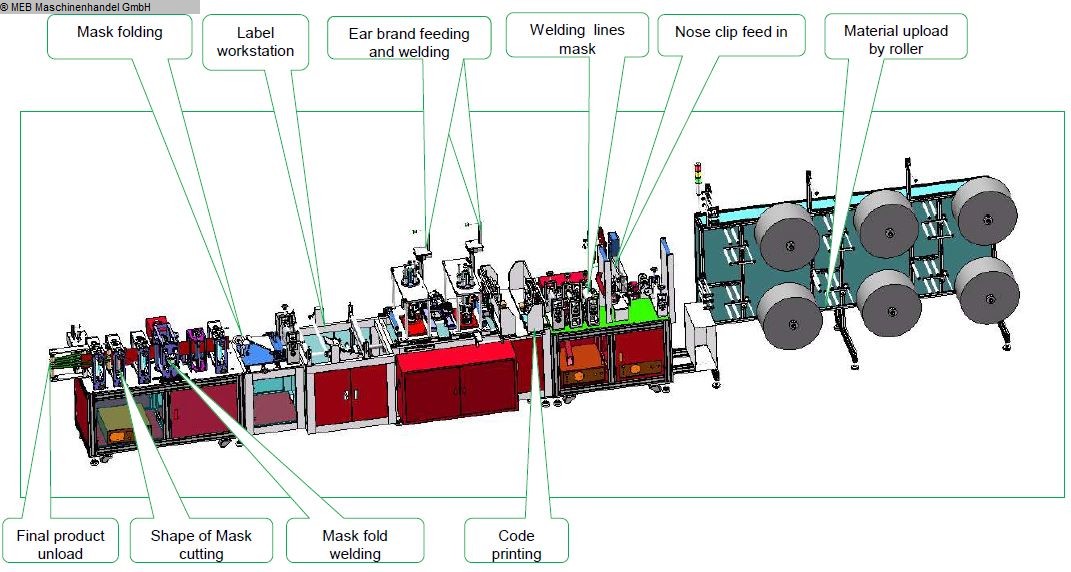

Condition: used - as good as new Specification: FFP 2 N95 mask system complete Consisting of: - see sketches in the plant - cycle time approx.: 35 - 50 pieces/min - not CE certified - Space requirement approx.: 9,657 x 1,472 x 1,985 mm - Completely assembled

- MEB Maschinenhandel GmbH

- Schwalbenweg 4

- 30826 Garbsen

- Deutschland

-

(0)5031 9394-634

-

info@meb-maschinenhandel.de

www.meb-maschinenhandel.de

#2037-G230102 · Plants, complete

K-W-H Langel Filtersysteme - Signa 18 / VEH 7500-C2 - - 2018 -

Technical details

Condition: used Specification: cartridge filter system for adjacent fan type: KWH-SIGA 18 with exhaust air system VEH 7500-C2 for transport of dry air without dust content or only with low dust content - used - year of construction: 2018 - Cartridge filter system type: KWH-SIMMA 18 - Fan in sound insulation bonnet type: VEH 7500-C2 - Motor power: 7,5 kW - Air volume: 7,500 m³/h - Negative pressure: 1,600 Pa

- MEB Maschinenhandel GmbH

- Schwalbenweg 4

- 30826 Garbsen

- Deutschland

-

(0)5031 9394-634

-

info@meb-maschinenhandel.de

www.meb-maschinenhandel.de

#2037-G200301 · Plants, complete

GERLACH Maschinenbau - Heissluft Shock Kanal 111 - - 2015 -

Technical details

- MEB Maschinenhandel GmbH

- Schwalbenweg 4

- 30826 Garbsen

- Deutschland

-

(0)5031 9394-634

-

info@meb-maschinenhandel.de

www.meb-maschinenhandel.de

#2037-G200701 · Plants, complete

HANS VON DER HEYDE - Pultrusions-/Heizlinie - - 2015 -

Technical details

- MEB Maschinenhandel GmbH

- Schwalbenweg 4

- 30826 Garbsen

- Deutschland

-

(0)5031 9394-634

-

info@meb-maschinenhandel.de

www.meb-maschinenhandel.de

#2037-G220102 · Plants, complete

NELA ROVI - Kontrollautomat fuer O-Ringe - - 2011 -

Technical details

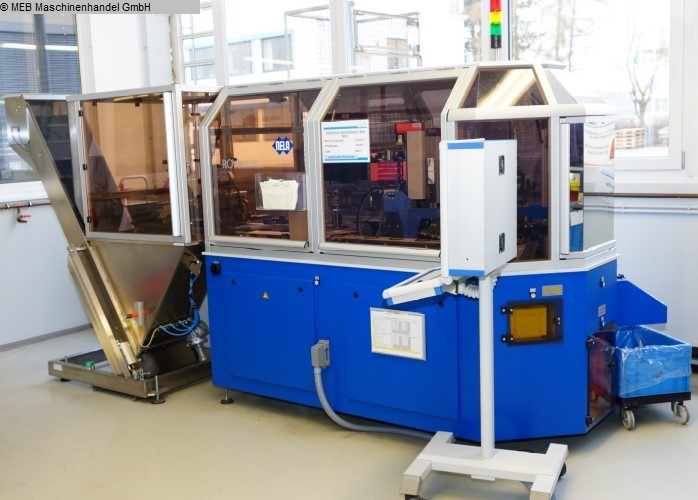

Condition: used Specification: automatic control machine for O-rings - second-hand rotary transfer machine with 16 pick-up stations - year of construction approx.: 2011 - pick-up stations: 16 - measuring range: ID from 55 - 90 mm cord from 2,5 - 3,5 mm (ID 55 - 70 mm) cord from 2.5 - 4.5 mm (ID 70 - 90 mm) - Part throughput: approx. 3 - 4 seconds per part approx. 900 - 1,200 parts per hour approx. 21,600 - 28,800 parts per day - Technical application: surface defect and crack detection on O-rings - Sorting function: Good, Bad, Undefined - Dimensions LxWxH approx.: 2,200 x 1,200 x 2,260 mm - Weight approx.: 1,000 kg Camera defective!

- MEB Maschinenhandel GmbH

- Schwalbenweg 4

- 30826 Garbsen

- Deutschland

-

(0)5031 9394-634

-

info@meb-maschinenhandel.de

www.meb-maschinenhandel.de

#2037-G220401 · Plants, complete

GERLACH - SHF-Kanal, Schockmodul + UHF - - 2003 -

Technical details

Condition: used, Specification: heating channel + shock module incl. UHF and PCT Typ: SHF 150-120-1-147-12 - length approx.: 12.000 mm - Consisting of: 9.000 mm hot air channel, incl. UHF 3.000 mm shock module with folding infeed conveyor and PCT - UHF power: 4x 3 kW - Temperature range UHF part: 240°C - 340°C - Temperature range shock module: 240°C - 500°C - Shock module with non-driven metal rollers - Extrusion height: 1,100 mm - Extrusion direction: from right to left - At the infeed and outfeed one 50 kW burner each - PCT burner capacity: 70 kW - Heating: gas heated - Control: Siemens S7 Relocation date no later than mid-June 2022.

- MEB Maschinenhandel GmbH

- Schwalbenweg 4

- 30826 Garbsen

- Deutschland

-

(0)5031 9394-634

-

info@meb-maschinenhandel.de

www.meb-maschinenhandel.de

#2037-G220402 · Plants, complete

GERLACH - Heizkanal HLK 150-1-110-12m - - 2003 -

Technical details

Condition: used, Specification: 12m heating duct incl. PCT - length approx.: 12.000 mm - extrusion height: 1.100 mm - extrusion direction: from right to left - belt width: 150 mm - Channel width: 190 mm - At the inlet and outlet there is a 50 kW burner each - In the PCT there is a 70 kW burner - Temperature range: 240°C to 340°C - Heating: gas heated - Belt speed: 2-40 m/min - Control: Siemens S7 Relocation date no later than mid-June 2022.

- MEB Maschinenhandel GmbH

- Schwalbenweg 4

- 30826 Garbsen

- Deutschland

-

(0)5031 9394-634

-

info@meb-maschinenhandel.de

www.meb-maschinenhandel.de

#2037-G220403 · Plants, complete

GERLACH - Nachheizkanal - - 1989/2015 -

Technical details

Condition: used, Specification: 21m post-heating duct with heat exchanger - length approx.: 21.000 mm - consisting of: 21.000 mm heating channel, incl. heat exchanger - extrusion height: 1.100 mm - Extrusion direction: from right to left - 4x burners with 50kW burner each - Tempering range: 240°C - 340°C - Heating: gas heated - Control system: Siemens Heating duct extension by 2x 3m, 2015 - The duct was extended by 2x 3m segments in 2016 - The burners of the 21,000 mm system were renewed in 2015

- MEB Maschinenhandel GmbH

- Schwalbenweg 4

- 30826 Garbsen

- Deutschland

-

(0)5031 9394-634

-

info@meb-maschinenhandel.de

www.meb-maschinenhandel.de

#2037-G181201 · Plants, complete

MEB - Batch-Off 700 - - -

Technical details

Condition: new Specification: Batch-Off-plant for rubber stripes - new - width stripes inlet up to 700 mm - maximum width value of rubber strip: 550 mm - input moving belt - rubber band stapler - stainless steel tank to contain release agent - stainless steel mesh band to extract the material - dry tunnel with 6 cooling fans 800 x 800 mm - length cooling section: about 8000 mm - output: fixed belt - storage: Wig-wag palletization system - total length of plant: about 12.000 mm - painting acc. to your specifications - safety guards: acc. to current standard - N.6 AC main motors on the line, driven by inverter systems - new electric cabinet and panels - on-board machine system new new construction with guarantee with CE mark and CE user and maintenance manual in English

TOP Manufacturer:

GERLACH - HAN S LASER - MEB - GERLACH MASCHINENBAU - K-W-H LANGEL FILTERSYSTEME - HANS VON DER HEYDE - NELA ROVI -