Lathes

Machinelist: Lathes

Automatic Curve Lathe

- STEINHAND GmbH

- Am Stahlwerk 15

- 45527 Hattingen

- Deutschland

-

+49 (0) 2324 / 977 26 - 01

+49 (0) 2324 / 977 26 - 99 -

info@steinhand.de

www.steinhand.de

#2026-1239 · Automatic Curve Lathe

WACHTLER - A25 GLE - - 2018 -

Technical details

Single spindle automatic lathe WACHTLER - A25 GLE with bar feeder Further information / scope of delivery: All accessories are included. The machine is in a well-maintained condition. Please refer to the offer for further technical details. Machine video available on request. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - #Tags: A 25 | A-25 | A25GLE

Ball-Turnig-Attachment

- IproMac e.K.

- Ennertsweg 38 b

- 58675 Hemer

- Deutschland

-

+49 (0) 170 27 32 014

-

w.schneegass@ipromac.de

www.ipromac.de

#2075-9026 · Ball-Turnig-Attachment

ARGUS - FLOWSERVE - Kugelbearbeitung - - 2000 - Siemens 840 D

Technical details

Ball machining center Special facility for balls 100 to 400 mm A viewing and demonstration is possible by appointment.

Bar Automatic Lathe - Multi Spindle

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20255 · Bar Automatic Lathe - Multi Spindle

TORNOS - MultiSwiss 8x26 - - 2018 - Fanuc

Technical details

CNC multi-spindle automatic lathe - Fanuc CNC Control TB-Deco - Oil cooling - All axes fully CNC - 1 x counter spindle - 4 x rear end machining - Belt conveyor for finished parts - 2x 80 bar high pressure pumps - Kraft & Bauer fire extinguishing system - Hinged belt conveyor - Bar loader - Paper belt filter - Including all existing processing units and accessories Running time 8,070 hours

- IVW GMBH

- Niederrheinstr.298

- 40489 Düsseldorf

- Deutschland

-

(0049)211-4184428

(0049)211-4184430 -

cd@ivwgmbh.com

www.ivwgmbh.com

#1088-E00962 · Bar Automatic Lathe - Multi Spindle

SCHÜTTE - S25 - 6 AC - - 2003 - CNC

Technical details

- Hans Klein Werkzeugmaschinenhandel GmbH

- Im Mühlgut 2-4

- 77815 Bühl

- Deutschland

-

0049 (0) 7223 9617-0

0049 (0) 7223 58512 -

info@klein-werkzeugmaschinen.de

www.klein-werkzeugmaschinen.de

#1052-03000 · Bar Automatic Lathe - Multi Spindle

INDEX - MS 25 E - - 1998 - INDEX

Technical details

- 6 cross slides - 6 longitudinal slides - polygon device - thread cutting device - hydr. tapping device - workpiece removal belt - bar loading magazine PIETRO CUCCHI, model AN-BN Accessories: various tool holders, various collets, chip conveyor, coolant

Bar Automatic Lathe - Single Spindle

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03829 · Bar Automatic Lathe - Single Spindle

INDEX - GS 42 - - 1989 - Siemens C 200

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03403 · Bar Automatic Lathe - Single Spindle

INDEX - ER 25 - - -

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03410 · Bar Automatic Lathe - Single Spindle

INDEX - GS30 - - - Index

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03412 · Bar Automatic Lathe - Single Spindle

INDEX - B 60 - - -

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03411 · Bar Automatic Lathe - Single Spindle

INDEX - B 60 - - -

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03409 · Bar Automatic Lathe - Single Spindle

INDEX - ER 25 - - -

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03408 · Bar Automatic Lathe - Single Spindle

INDEX - ER 25 - - -

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03405 · Bar Automatic Lathe - Single Spindle

INDEX - ER 25 - - -

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03404 · Bar Automatic Lathe - Single Spindle

INDEX - ER 25 - - -

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03402 · Bar Automatic Lathe - Single Spindle

INDEX - ER 25 - - -

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03407 · Bar Automatic Lathe - Single Spindle

INDEX - ER 25 - - -

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03406 · Bar Automatic Lathe - Single Spindle

INDEX - ER 25 - - -

Technical details

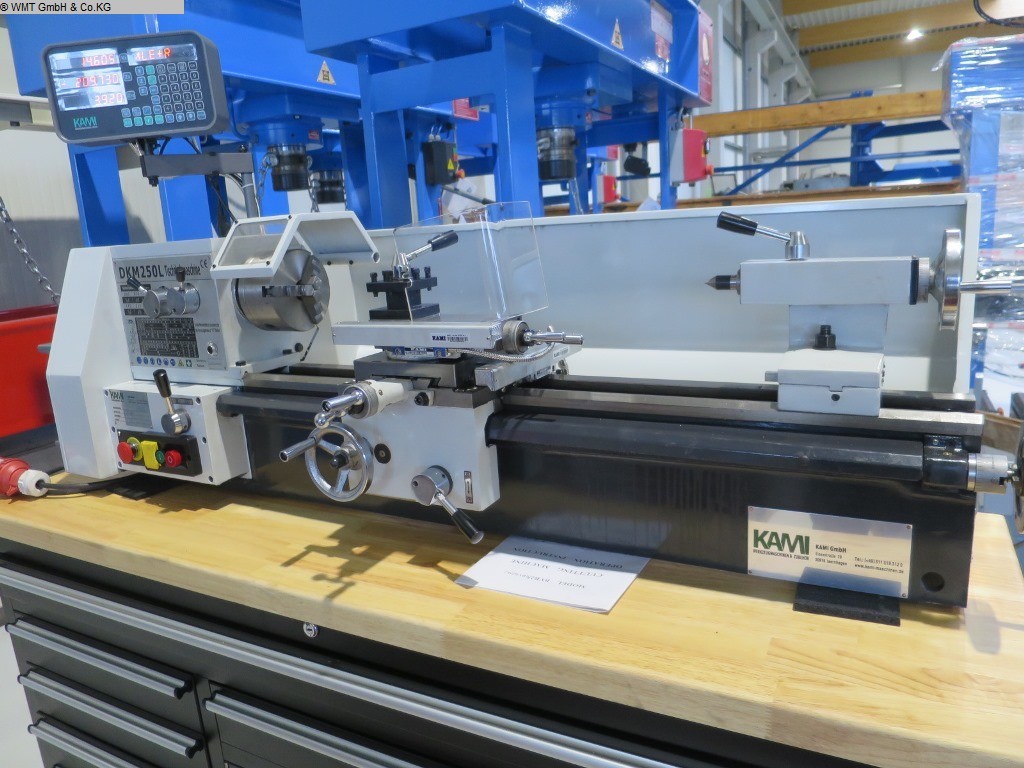

Bench Lathe

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-78007 · Bench Lathe

KAMI - DKM 250V.550 - - -neu- -

Technical details

Equipped with - 20 mm spindle passage - adjustable guideways - Powerful 1.0 kW motor - continuously variable speed Scope of delivery: - 3-jaw chuck 100 mm, - 4-jaw faceplate chuck 125mm - standing and rotating bezel - Splash guard - Feed protection

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-78003 · Bench Lathe

HBM - 250 x 550 Norton Profi - - -neu- -

Technical details

Speed in 6 levels 125 - 2000rpm. 3-jaw chuck 125 mm. 4-jaw chuck 125 mm. (Independent) Fixed bezel. Revolving bezel. 4-fold steel holder. chip tray. back panel. spindle protection. Hardened bed rails. Longitudinal feed with left / right switching. Set of change gears. Associated Tools.

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-78005 · Bench Lathe

ELMAG - Superturn Vario mit MFB Vario - - -neu- -

Technical details

3-axis LCD digital display system longitudinal feed. 3-jaw chuck 125 mm. 4-way steel holder. chip tray, bulkhead Hardened bed tracks. Emergency stop switch. lining protection Tool box, instruction manual.

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-78001 · Bench Lathe

KAMI - DKM 250L - - -neu- -

Technical details

Equipped with - 27 mm spindle clearance - adjustable guideways - Powerful motor with 0.75 kW - High resolution of the axis spindles for exact positioning - Danger!! without digital display Scope of delivery: 3-jaw chuck 100 mm, change gear set, splash guard. On request also with 230 volt connection

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-78002 · Bench Lathe

HBM - 250 x 550 Profi Vario - - -neu- -

Technical details

Benchtop lathe with base cabinet 3-axis LCD digital display system fully assembled. Longitudinal feed. 3-jaw chuck 125 mm. 4-jaw chuck 125 mm. Clamping plate. 4-way steel holder. Clock for thread cutting. Drip tray Hardened bed tracks. Emergency stop switch. Forage protection Set of wheels. Appropriate tools.

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-78000 · Bench Lathe

KAMI - DKM 250L-1 - - -neu- -

Technical details

Equipped with - 2-axis digital measuring system with position indicator - manufactured according to DIN 8606 - 27 mm spindle passage - adjustable guideways "by adjustable strips" - Strong engine with 0.75 kW - High resolution of the axis spindles for exact positioning Delivery: 3-jaw chuck 100 mm, change gear set, splash guard 3-axis digital measuring system fully assembled.

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-78004 · Bench Lathe

ELMAG - Superturn 250 x 550 Vario - - -neu- -

Technical details

longitudinal feed. 3-jaw chuck 125 mm. 4-way steel holder. chip tray, bulkhead Hardened bed tracks. Emergency stop switch. lining protection Tool box, instruction manual.

Lathes have stood the test of time as some of the most efficient and multi-functional tools. They can be used on a wide variety of material surfaces and can serve a huge number of functions. Whether you need a small lathe for home use or an industrial size lathe for large-scale production, you can find the perfect piece of used equipment to suit your needs at LagerMaschinen. Visit this easy-to-use forum to find the best used machinery for your needs.

LagerMaschinen - your home for used machinesLathes are critical pieces of equipment in a wide variety of sectors. A lathe is capable of grinding, cutting and finishing tiny parts for watch- and jewellery-making, as well as large-scale pieces for automobiles and airplanes. Whether you prefer the control offered by a manually operated lathe or the precision and efficiency of a computer numerical controlled (CNC) lathe, you can find a huge selection at LagerMaschinen, your best source for used machinery.

Buying used machines is a smart investmentSmart shoppers know that you dont have to sacrifice quality for affordability when buying machinery for your home or business. Buying used machines is a great way to get the quality you need without straining your budget. If youre in the market for lathes, saws, grinders or any other equipment, you can find a great selection of used machines at LagerMaschinen. Sort results by price, location or brand and find the best used machines around.

TOP Manufacturer:

ZMM - KRAFT - GILDEMEISTER - INDEX - WEILER - MORI SEIKI - COLCHESTER - HUVEMA - MAZAK - BERNARDO -