JS-Werkzeugmaschinen GmbH - Stockist for used machines

Machinelist:

CNC Lathe

- JS-Werkzeugmaschinen GmbH

- Weserstrasse 228

- 32545 Bad Oeynhausen

- Deutschland

-

+49 (0) 163 - 6037450

-

info@js-wzm.de

www.js-wzm.de

#2062-PRO13N · CNC Lathe

HANKOOK - Protec 13N - - 2023 - Fanuc 0i-TB/F

Technical details

Heavy Duty CNC Turning Lathe HANKOOK PROTEC 13N x 2.000 - 8.000 high-performance CNC lathe Features Suitable for large diameter workpiece ( Ø1100mm) Up to 8,000mm (315 ) shaft turning length Large 8 tons (17,600lbs) load capacity between centers Automatic shifting 4 or 2 speed geared head stock Big bore spindle Ø330 Extra wide one-piece cast iron bed Induction-hardened and precision-ground guide ways High precision ball screws and servo motors for both axes Square tool post featuring Curvic coupling Powerful 37kW(50HP) spindle motor Built-in live tailstock spindle ( Ø200mm quill dia.) Rapid feed device for tailstock body Guidance hand-wheel (simultaneous 2 axes control) X/Z axes electronic hand-wheels (MPG) Full automatic lubrication to all critical areas

Datasheet

Request / Contact

- JS-Werkzeugmaschinen GmbH

- Weserstrasse 228

- 32545 Bad Oeynhausen

- Deutschland

-

+49 (0) 163 - 6037450

-

info@js-wzm.de

www.js-wzm.de

#2062-PT1250 · CNC Lathe

WOHLENBERG - PT 1 - 1250 II - - 2000 - Sinumerik 840C

Technical details

Datasheet

Request / Contact

Lathe - cycle-controlled

- JS-Werkzeugmaschinen GmbH

- Weserstrasse 228

- 32545 Bad Oeynhausen

- Deutschland

-

+49 (0) 163 - 6037450

-

info@js-wzm.de

www.js-wzm.de

#2062-PRO11N · Lathe - cycle-controlled

HANKOOK - Protec 11N - - 2023 - Fanuc 0i-TB/F

Technical details

Heavy Duty CNC Turning Lathe HANKOOK PROTEC 11N x 2.000 - 8.000 high-performance CNC lathe Features Suitable for large diameter workpiece ( Ø1100mm) Up to 8,000mm (315 ) shaft turning length Large 8 tons (17,600lbs) load capacity between centers Automatic shifting 4 or 2 speed geared head stock Big bore spindle Ø330 Extra wide one-piece cast iron bed Induction-hardened and precision-ground guide ways High precision ball screws and servo motors for both axes Square tool post featuring Curvic coupling Powerful 37kW(50HP) spindle motor Built-in live tailstock spindle ( Ø200mm quill dia.) Rapid feed device for tailstock body Guidance hand-wheel (simultaneous 2 axes control) X/Z axes electronic hand-wheels (MPG) Full automatic lubrication to all critical areas

Datasheet

Request / Contact

Vertical Turret Lathe - Double Column

- JS-Werkzeugmaschinen GmbH

- Weserstrasse 228

- 32545 Bad Oeynhausen

- Deutschland

-

+49 (0) 163 - 6037450

-

info@js-wzm.de

www.js-wzm.de

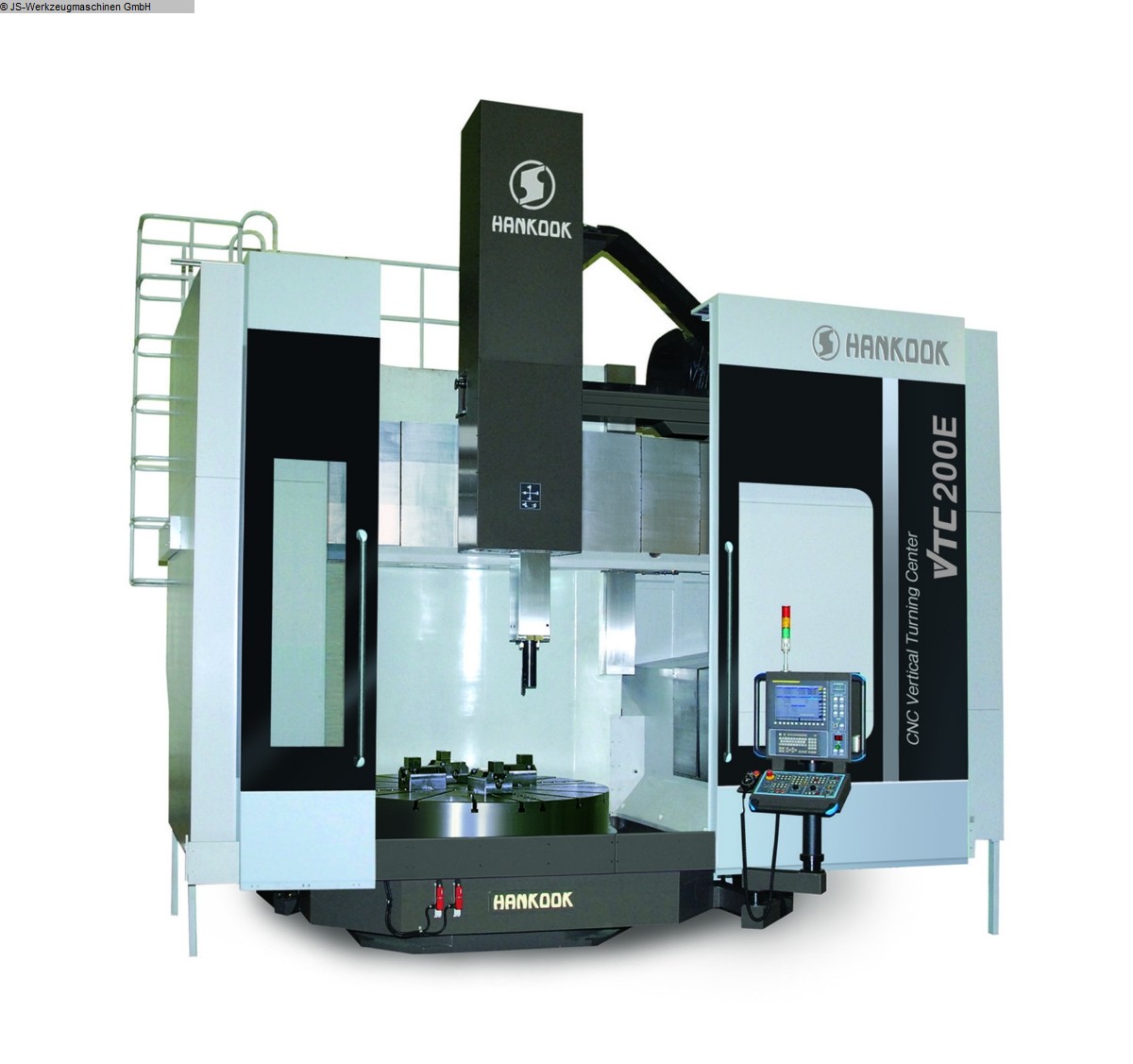

#2062-4444 · Vertical Turret Lathe - Double Column

HANKOOK - VTC-200 E - - 2022 - Fanuc 32i-A

Technical details

TECHNICAL DESCRIPTION Vertical Turret Lathe - Single Column HANKOOK VTC-200E Heavy Duty High Precision Vertical Turning Lathe. - Casting bed with strong ribs, hardend and smoothed box way guide are ensure for high precision and working life.Each guideways for feeding axis is lubricated and attached with Turcite to be reduced wear and friction- resistance. - Tool Changer: 24 slots of tools also 12 for driven tools for a tool weight up to 70 kg - Axis drive system:Big ball screws coupled with digital servo motors and linear scales guarantee high reproducibility and precision in positioning. - Control system: Fanuc 32i-A - Standard accessories: 4 jaws face plate with 2.000mm diameter Automatic Tool Changer Hydraulik unit Central lubrication Coolant tank Telescopic cover Work light Patrol lamp (Red, Yellow, Green) Levelling block Foundation bolt & nut Operation tool box & tool kits CE conformity mark

Datasheet

Request / Contact

Vertical Turret Lathe - Single Column

- JS-Werkzeugmaschinen GmbH

- Weserstrasse 228

- 32545 Bad Oeynhausen

- Deutschland

-

+49 (0) 163 - 6037450

-

info@js-wzm.de

www.js-wzm.de

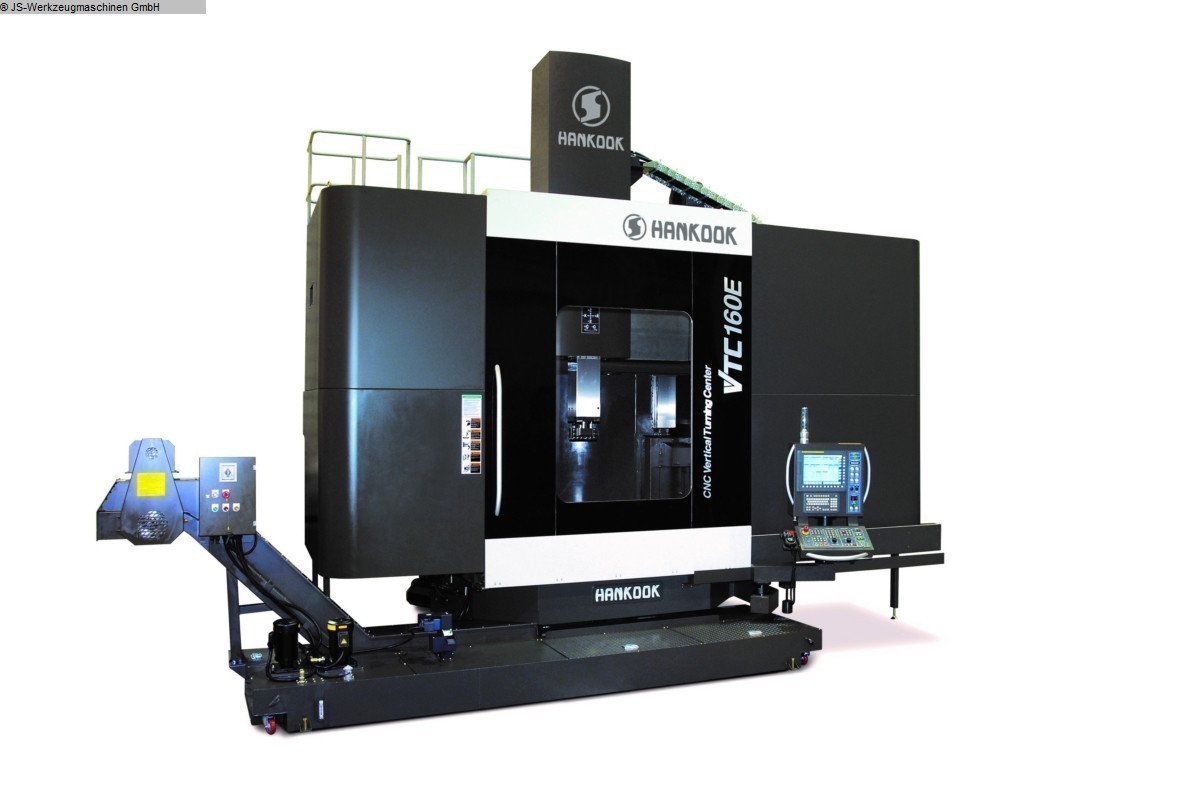

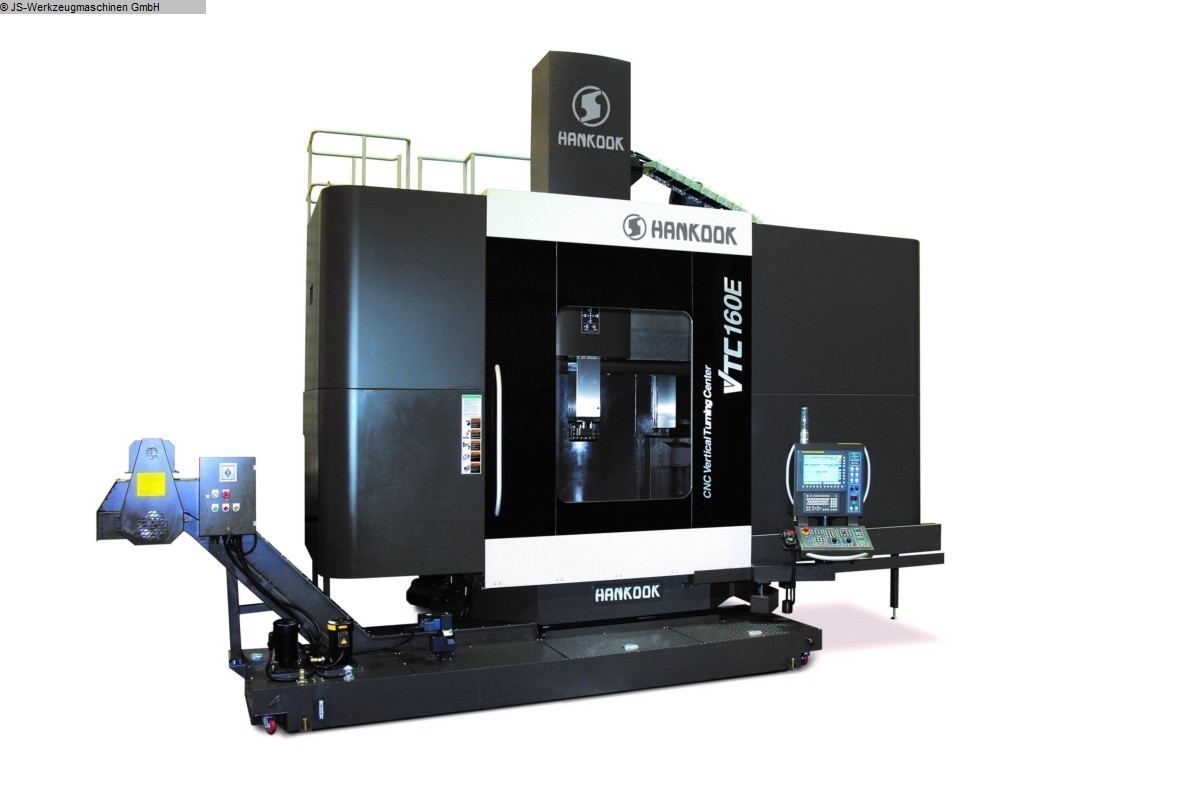

#2062-125E · Vertical Turret Lathe - Single Column

HANKOOK - VTC-125 E - - 2023 - Fanuc 0i-TF

Technical details

TECHNICAL DESCRIPTION Vertical Turret Lathe - Single Column HANKOOK VTC-160E Heavy Duty High Precision Vertical Turning Lathe. - Casting bed with strong ribs, hardend and smoothed box way guide are ensure for high precision and working life.Each guideways for feeding axis is lubricated and attached with Turcite to be reduced wear and friction- resistance. - Tool Changer: 24 slots of tools also 12 for driven tools for a tool weight up to 70 kg - Axis drive system:Big ball screws coupled with digital servo motors and linear scales guarantee high reproducibility and precision in positioning. - Control system: Fanuc 0i-T - Standard accessories: 4 jaws face plate with 1.600mm diameter Automatic Tool Changer Hydraulik unit Central lubrication Coolant tank Telescopic cover Work light Patrol lamp (Red, Yellow, Green) Levelling block Foundation bolt & nut Operation tool box & tool kits CE conformity mark

Datasheet

Request / Contact

- JS-Werkzeugmaschinen GmbH

- Weserstrasse 228

- 32545 Bad Oeynhausen

- Deutschland

-

+49 (0) 163 - 6037450

-

info@js-wzm.de

www.js-wzm.de

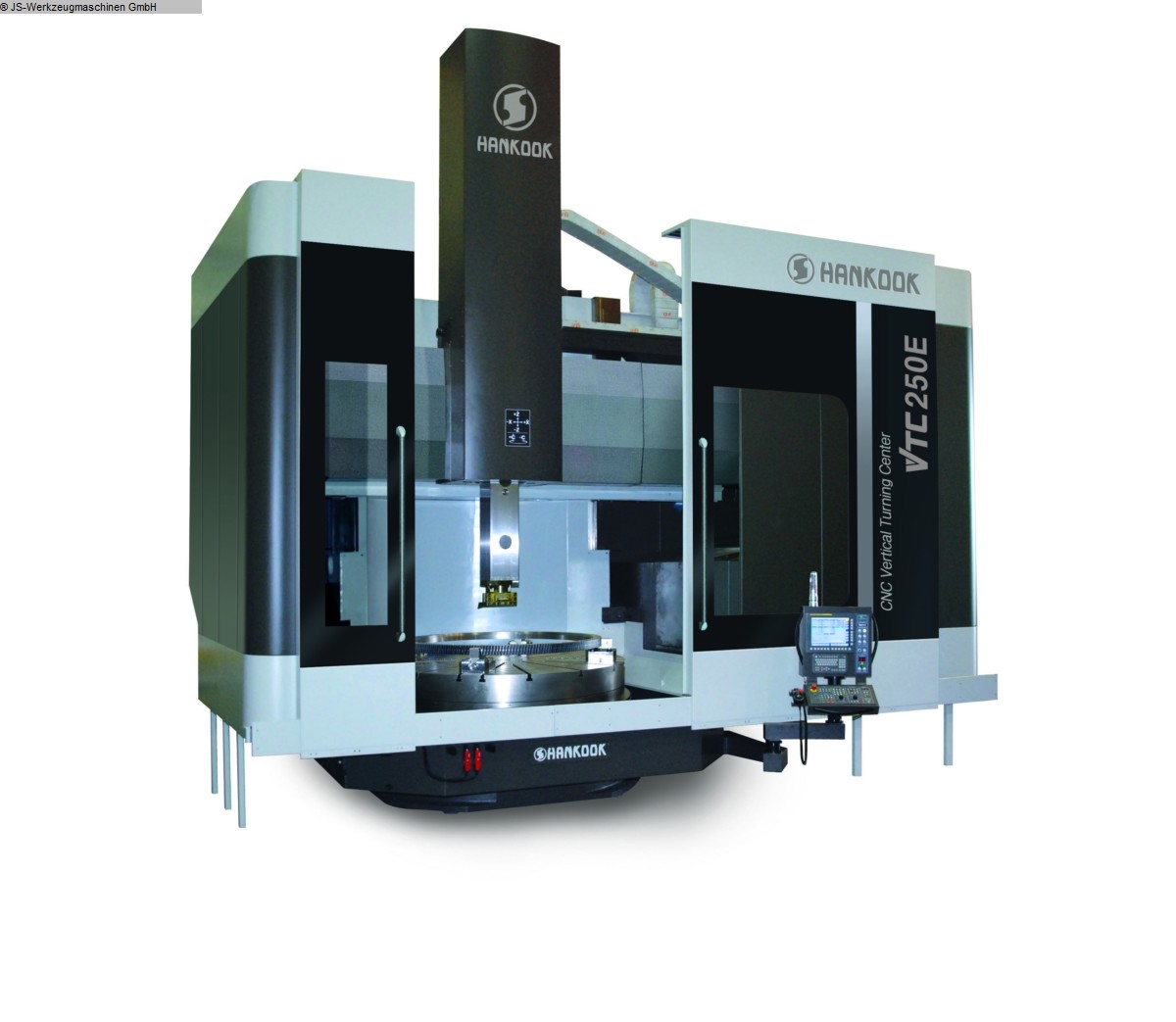

#2062-3333 · Vertical Turret Lathe - Single Column

HANKOOK - VTB-250E - - 2021 - Fanuc 32i-B

Technical details

TECHNICAL DESCRIPTION Vertical Turret Lathe - Single Column HANKOOK VTB-250E Heavy Duty High Precision Vertical Turning Lathe. - Casting bed with strong ribs, hardend and smoothed box way guide are ensure for high precision and working life.Each guideways for feeding axis is lubricated and attached with Turcite to be reduced wear and friction- resistance. - Tool Changer: 12 slots of tools for a tool weight up to 70 kg - Axis drive system:Big ball screws coupled with digital servo motors and linear scales guarantee high reproducibility and precision in positioning. - Control system: Fanuc 32i-B - Standard accessories: 4 jaws face plate with 2.500mm diameter Automatic Tool Changer Hydraulik unit Central lubrication Coolant tank Telescopic cover Work light Patrol lamp (Red, Yellow, Green) Levelling block Foundation bolt & nut Operation tool box & tool kits CE conformity mark The illustration shows a VTC-250E. However, figures are very similar. VTB has no driven tools and no C-axis.

Datasheet

Request / Contact

- JS-Werkzeugmaschinen GmbH

- Weserstrasse 228

- 32545 Bad Oeynhausen

- Deutschland

-

+49 (0) 163 - 6037450

-

info@js-wzm.de

www.js-wzm.de

#2062-2222 · Vertical Turret Lathe - Single Column

HANKOOK - VTC-160 E - - 2021 - Fanuc 0i-T

Technical details

TECHNICAL DESCRIPTION Vertical Turret Lathe - Single Column HANKOOK VTC-160E Heavy Duty High Precision Vertical Turning Lathe. - Casting bed with strong ribs, hardend and smoothed box way guide are ensure for high precision and working life.Each guideways for feeding axis is lubricated and attached with Turcite to be reduced wear and friction- resistance. - Tool Changer: 24 slots of tools also 12 for driven tools for a tool weight up to 70 kg - Axis drive system:Big ball screws coupled with digital servo motors and linear scales guarantee high reproducibility and precision in positioning. - Control system: Fanuc 0i-T - Standard accessories: 4 jaws face plate with 1.600mm diameter Automatic Tool Changer Hydraulik unit Central lubrication Coolant tank Telescopic cover Work light Patrol lamp (Red, Yellow, Green) Levelling block Foundation bolt & nut Operation tool box & tool kits CE conformity mark

Datasheet

Request / Contact

JS-Werkzeugmaschinen GmbH

Weserstrasse 228

Contact Trader

JS-Werkzeugmaschinen GmbH

Weserstrasse 228

32545 - Bad Oeynhausen

Deutschland

+49 (0) 163 - 6037450

info@js-wzm.de

www.js-wzm.de

Contact person:

Herrn Jörg Schröder +49 (0) 163 - 6037450

Weserstrasse 228

32545 - Bad Oeynhausen

Deutschland

+49 (0) 163 - 6037450

info@js-wzm.de

www.js-wzm.de

Contact person:

Herrn Jörg Schröder +49 (0) 163 - 6037450

Machine category

CNC Drehmaschine · Drehmaschine - zyklengesteuert · Karusselldrehmaschine - Doppelständer · Karusselldrehmaschine - Einständer · Portalfräsmaschine ·