Engelfried Maschinentechnik GmbH - Stockist for used machines

Machinelist:

Glazing bead sww

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2718 · Glazing bead sww

HECHT - Exenso DS350E - Video - - - Vorführmaschine - ja/CNC

Technical details

HECHT double miter saw Exenso DS350E - 3000 mm ----------------------------------------------------- For wooden glazing beads, sash bars, profile strips, aluminum strips, etc. Pos. 1.1 article number 942.5103 HECHT Exenso DS350E - Working length 3000 mm - Pivoting range 22.5° (inside) to 135° (outside) - right head moveable - Saw blade holder Ø 350 mm - incl. 1 pc center support. - Pneumatic clamping of the aggregates. - Positioning control Exenso DS3 with touch panel 15" display in the dust-proof monitor housing. - 3-axis control, 1 longitudinal axis and 2 swivel axes. - Input of the cutting data by hand - Processing data from a cutting list (data set by default) - Processing of measuring rod data (radio caliper GMF) - Ethernet port 10/100 (TCP/IP) - USB interface - incl. Control cabinet, motor and software licenses. Pos. 1.2 article number 942.5997 DS feed device pneumatic Pos. 1.3 article number 942.5236 DS workpiece clamping combined Combined workpiece clamping consisting of: Pneumatic swing clamp for clamping the material from above. (Free access to the work table) Pneumatic horizontal clamp - torsion-proof clamping cylinder with pressure piece. The clamps can be selected individually via the saw control. The clamping sequence can also be set via the control. Including safety preload pressure Scope of delivery: 1 swing clamp / 1 horizontal clamp Pos. 1.4 article number 723.0121 DS saw blade HM 350x3.0/2.2/30 Z 100 (wood G5) Helical/ helical/flat tooth - positive Pos. 1.5 article number 942.5201 ES / DS workpiece clamping from the front - 2 clamping cylinders secured against rotation - 2 cylinder holders with clamping lever Pos. 1.6 article number 942.5241 DS350 Table Pads Grooved "Standard" Pos. 1.7 article number 942.5237 DS Software "Excess length" (subsequent steps must be confirmed) Process control including hardware. After entering a cutting size > max. cutting length of the system, the cutting is cycled. (Left unit cuts, right unit shifts the material and cuts made to measure.) Article number 945.2007 Packaging DS350 (transport frame) ----------------------------------------------------- Total price in this version - on request! Options with extra charge on request: ----------------------------------- Article number 944.1023 GMF vernier caliper 3000mm complete set (1500mm plus extension 1500mm) including charger and receiver. A robust aluminum measuring bar with a measuring range of 3,000 mm ideal for measuring the glazing beads. functionality For use on doors and large window sashes, the vernier caliper GMF safely and quickly mechanically extended up to a measuring length of 3,000 mm will. Base length: 1,500 mm Extension: 1,500 mm, automatic detection Accuracy of ±0.1mm Resolution of 0.02mm. Measurement transmission via radio interface to the controller or to the PC. Microcontroller charger for battery pack 100-240V input voltage and Euro/UK/US/AUS power adapter. Article number 945.2006 Packaging GMF tube Ø220x2000 mm Article number 942.5241 DS350 Table Pads Grooved according to customer's sample The mounted table pads are made according to the customer's drawing milled Control by your window construction software: -------------------------------------- No problem: Hecht's software department will also help you with customization of your existing data record for transfer to the saw! Price based on effort, please ask us! For our new machine offers, please also note options such as Working length 4,000 mm Hydro-pneumatic saw feed (for aluminium) Spray device for aluminum saws radio measuring stick and much more! (Technical information according to the manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6760 · Glazing bead sww

RUCHSER - RU-GL-45° - - neu - ,

Technical details

RUCHSER RU-GL-45° ----------------------------------------------------- Glazing bead saw at the sliding work table Developed for cutting glazing beads in pairs on the sliding work table The RU-GL glazing bead saw is mounted on a sliding work table with Scanning and clamping device for two glazing beads. Cutting length min. 230 mm, max. 2380 mm. Left saw stuck right saw on carriage mounted to be moved manually. Pneumatic clamping device from above and from the side, safety two-hand operation. Saw motors 0.37 kW, voltage 400V. Sliding work table with felt pad, length with side shelf 3300 mm, Width 1400 mm, working height 800 - 1000 mm. Pneumatically lowerable Counter bearing for positioning the wings. Pos. 1: RU-GL double glass bead saw 45° on the RU-SA-3000 ----------------------------------------------------- for glazing beads up to 30 x 70 mm (W x H) !!!, Mounted on the sliding work table with scanning and Clamping device for two glazing beads. Cutting length min. 230 mm, max. 2380 mm. Left saw fixed, right saw on carriage manually movably mounted. Pneumatic clamping device from above and from the side, safety two-hand operation. Saw motors 0.37 kW, voltage 400V. Sliding work table with felt pad, length with side shelf 3300 mm, width 1400 mm, Working height 800 - 1000 mm. Pneumatically lowerable Counter bearing for positioning the wings. ----------------------------------------------------- Basic price in the above version: on request! ----------------------------------------------------- Ex works. Plus packaging and shipping and current Material cost surcharge of 6% of the gross price Options with additional costs: ----------------------------------------------------- Item 1.1 Set of shims for rebated glazing beads for RU-GLS-P45° and RU-GLS-ED45° Price request after checking the glazing beads. Depending on the number of glazing beads used, this can happen several sets of supplements are required. To determine the exact number to be able to we need profile drawings before order confirmation the glazing beads to be used. Surcharge: on request, after sending your glazing bead drawings Pos. 1.2 recording device for scanning gauge RU-GL for transferring the scanning dimensions to the saw with pneumatic installation. Surcharge: 539.00 euros Pos. 1.3 Feeler gauge for glazing beads, total length 2550 mm, max. scanning length approx. 2450 mm Gauge made of square profile with 2 fixed and 2 adjustable cams for scanning the glazing bead length Surcharge: 421.00 euros Pos. 1.4 Feeler gauge for glazing beads, overall length 1500 mm, max. scanning length approx. 1430 mm Gauge made of square profile with 2 fixed and 2 adjustable cams for scanning the glazing bead length Surcharge: 378.00 euros Pos. 1.5 operating time switching device for independent suction. Adjustable from 5 sec. up to 3 hours with each sawing process automatically becomes the set time sucked off. Will be repeated within the suction time sawn, the set suction time begins again from the beginning. Surcharge: 620.00 euros All prices in euros, net, plus statutory VAT (technical information according to the manufacturer, without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6761 · Glazing bead sww

RUCHSER - RU-GL-45° - - neu - ,

Technical details

Ruchser RU-GLS-ED 45° glass bead saw -------------------------------------- Developed for cutting glazing beads in pairs The RU-GLS-ED45° double glazing bead saw must be adjusted to size manually. the Machine was designed for cutting glazing beads in pairs with a cutting angle of 45° and features a fixed and a movable saw unit. The manual length adjustment is equipped with an electrical digital display. It can cut lengths from 240mm - 2650mm be sawn. During the cutting process, the glazing beads with a pneumatic clamping device clamped from above and from the front to prevent tilting to prevent the glazing beads. Operation is via a safety two-hand operation Item 1: RU-GLS-ED45° double glazing bead saw ----------------------------------------------------- with manual measurement, for the pairwise Cutting glazing beads, cutting angle 45°. Manual length adjustment with electric Digital display, cutting length from 150 - 2650 mm. Pneumatic clamping device from above and from in front. Safety two-hand operation, saw blade diameter 250mm, length 3700mm, width 700mm, Voltage 400V ----------------------------------------------------- Basic price in the above version: on request! ----------------------------------------------------- Ex works. Plus packaging and shipping and current Material cost surcharge of 6% of the gross price Options with additional costs: ----------------------------------------------------- Item 1.1 Set of shims for rebated glazing beads for RU-GLS-P45° and RU-GLS-ED45° Price request after checking the glazing beads. Depending on the number of glazing beads used, this can happen several sets of supplements are required. To determine the exact number to be able to we need profile drawings before order confirmation the glazing beads to be used. Surcharge: on request, after sending your glazing bead drawings Pos. 1.2 recording device for scanning gauge RU-GL for transferring the scanning dimensions to the saw with pneumatic installation. Surcharge: 539.00 euros Pos. 1.3 Feeler gauge for glazing beads, total length 2550 mm, max. scanning length approx. 2450 mm Gauge made of square profile with 2 fixed and 2 adjustable cams for scanning the glazing bead length Surcharge: 421.00 euros Pos. 1.4 Feeler gauge for glazing beads, overall length 1500 mm, max. scanning length approx. 1430 mm Gauge made of square profile with 2 fixed and 2 adjustable cams for scanning the glazing bead length Surcharge: 378.00 euros Pos. 1.5 operating time switching device for independent suction. Adjustable from 5 sec. up to 3 hours with each sawing process automatically becomes the set time sucked off. Will be repeated within the suction time sawn, the set suction time begins again from the beginning. Surcharge: 620.00 euros All prices in euros, net, plus statutory VAT (technical information according to the manufacturer, without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2726 · Glazing bead sww

Wegoma -STRIMA - 2750 - - gebraucht - ja

Technical details

Glass bead saw Striffler-Strima 2750 --------------------------------- Saw blade diameter: 250 mm Distance sawing max 90°: 2,800 mm Cutting height at 90°: 80 mm Cutting width: 2,200 mm Cutting height at 45°: 28 mm Distance sawing min. 90°: 260 mm Saw blades tilt up to: 45° Main engine: 1.1 kW Saw blades tiltable: Yes Pneumatic clamp: Yes Control: program control Execution: cutting from behind Width adjustment: electric motor Weight approx.: 400 kg CE mark: Yes Space requirement: Length: 3,250mm Width: 1,200 mm Height: 1,100mm --------------------------------- (technical data according to the manufacturer - no guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6842 · Glazing bead sww

STRIFFLER - 2750 E - - gebraucht - ja 0

Technical details

STRIFFLER double glass bead miter saw 2750 E --------------------------------- with electronic positioning device Cutting length in special version: 2200 mm Min. cutting length: 254 mm Saw feed is pneumatic, infinitely adjustable with oil brake cylinder Length adjustment by recirculating ball - threaded spindle - servo Motor drive and electric. Positioning device Cutting angles 90° and 45° against adjustable fixed stops, Intermediate positions adjustable according to scale. Clamping device from the front up to a maximum workpiece thickness of 65 mm Clamping device from the front and from above up to a maximum workpiece thickness of 65 mm up to a maximum workpiece height of 50 mm Connection for suction diameter 50 mm Electrical connection: 3 m cable for 380 volt, 6.0 amp plug. Electrical circuit: Control cabinet with main switch, push button for: Control on, saw motors, dead man button for 500 mm Danger area, EMERGENCY STOP, El. Pos. Device, connection cable Longitudinal drive: positioning motor 0.25 KW with brake, Travel speed 7 m/min. Saw blade drive: 2 x 1.1 KW three-phase motors 2,800 rpm via V-belt = 5,000 rpm Saw blades: HM equipped, D = 250 mm, bore 20 mm, Wing measuring stick Weight approx. 450 kg -------------------------------- Price of the above machine on request! -------------------------------- (technical data according to manufacturer - no guarantee!)

Datasheet

Request / Contact

Horizontal slot mortising machine

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5420 · Horizontal slot mortising machine

GOETZINGER - SYSTEM HOFFMANN HR 150 - - neu -

Technical details

Götzinger HR 150 - Hoffmann system The machine that gives you the highest precision when drilling two levels guaranteed. Frame and slot drilling machine, enables drilling in two levels in one clamping. - Well thought-out, precise and practical stop system - particularly smooth and play-free grid positioning, Feed and transverse adjustment - Guidance systems for the highest demands - Special drill chuck - precise, quiet concentricity - for drilling levels via digital display - Two side stops offer enormous advantages, center stop on request - Continuous front stop with position markings - Drilling pattern depending on the wood profile - free choice, in a 12 mm grid Special grids also possible - integrated dust extraction - the exchangeable additional equipment (e.g. drill heads, Miter stops, parapet railing device, side and folding stops) can be easily installed without tools. and dismantle. Technical data: ******************** Drilling unit ------------------ Height adjustment in 2 levels via digital display Height adjustment 100 mm pneumatically Drilling stroke/depth 150 mm by hand Transverse adjustment 320 mm via grid Drilling pattern width 12 mm pitch, standard Three-phase motor 230/400 V, 50 Hz, 1,420/2,840 rpm, 1.3-1.8 KW Tool holder --------------------------- Special drill chuck with 2 tool changing inserts 1 x M10, 1 x D 16 stop system ---------------------- 2 side stops can be swiveled in/out 1 longitudinal stop (tube) with adjustable folding stop approx. 1500 mm Elongated hole stop left and right Workpiece clamping --------------------------- pneumatically via foot valve Dust extraction Special accessories - see PDF attachment (technical data according to manufacturer - no guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5421 · Horizontal slot mortising machine

GOETZINGER - SYSTEM HOFFMANN HF 150 E - - neu -

Technical details

Datasheet

Request / Contact

Laminating press

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6102 · Laminating press

TRIMWEX - SLV-H-6.0-1.2-120-6V-II-P - - neu -

Technical details

1 pc. LAMINATION PRESS Type SLV - H - 6.0 - 1.2 - 120 - 6V - II -P -------------------------------------------------------- Technical specifications -------------------------------------------------------- working dimensions: Length: 6000mm Height: 1200mm Gluing thickness: 20 - 120 mm Number of pressure cylinders: 12 pcs. Cylinder type: Ø 63 x 120 mm Max. force per pressure cylinder: 50 kN Specific pressure: 7.5 kg/cm2 Number of hold-down devices: 6 pcs. Cylinder type: Ø 40 x 100 mm Max. force per hold-down device: 20 kN Number of sections: 2 Max. pressure: 160 bar Power: 3.0kW Pump flow: 10L/min Manual control with hydraulic valves every work surface in contact with glue is covered with INOX Materila covered each pressure cylinder and the hold-down device can be locked separately equal pressure in each section The press can be extended in the future Parking space for 2 x 3 hold-down devices Italian hydraulics -------------------------------------------------------- Price in this equipment on request! -------------------------------------------------------- Option: German hydraulics surcharge 2,300.00 euros Other options on request! Description of basic machine: -------------------------------------------------------- The gluing stand type SLV - H - 120 - 6.0 - 1.2 is for gluing the profiles in of various shapes (window scantlings, supporting profiles, etc.). The largest dimensions of the glued piece are 6000 x 1200 x 120 mm. The compression is carried out by hydraulic cylinders with a diameter of 63 mm and a stroke of 120 mm, which exert a force of 50 kN per unit at a pressure of 160 bar. There are 12 hydraulic cylinders on the gluing stand, which generate the total force of 600 kN. The gluing stands with the pressure cylinders are adjustable in width (left and right). (Pressure cylinder height-adjustable from 650 to 1200 mm - is available as an OPTION). The lower stops are fixed and are in one piece. The workpiece to be pressed is through 6 alignment units aligned with a hydraulic cylinder. The hydraulic cylinders have a diameter of 40 mm and a stroke of 120 mm and they exert the force of 20 kN per unit at a pressure of 160 bar. The hydraulics are operated by means of the manually controlled valves; when the valve lever is in the position "compression" is reached after reaching the set Pressure interrupts the pressing (Technical data according to the manufacturer - without guarantee!)

Datasheet

Request / Contact

Olive boring machine

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6783 · Olive boring machine

GANNER - Olivenbohrmaschine - - gebraucht -

Technical details

Ganner olive drilling machine Still in use and to visit!

800 €

Datasheet

Request / Contact

Order picking carriage

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6779 · Order picking carriage

RUCHSER - RU-KWI-S - - Neu -

Technical details

Commission car RU-KWI-S --------------------------------------- The RU-KWI-S is for internal and truck transport. In When unloaded, it can be nested. For forklift and Suitable for crane transport. --------------------------------------- Equipment and accessories: -With a removable crossbeam so that the consignment trolleys are unloaded State can be pushed into each other. -With 4 crane hooks, 4 forklift brackets and 4 lashing strap holders. -Mobile on 4 polyamide swivel castors Ø 150 mm, 2 of which have brakes. -Steering rollers can be removed, so the commission trolley can stand securely on the truck. -Other equipment and accessories as for RU-KWI. --------------------------------------- Technical details RU-KWI-1600S: - Length 1,720mm - Width 1,000mm - Height 1,950mm - System height 1,500 mm - Usable width 700 mm - Weight 85kg The painting is done in the colors RAL 7038 (grey) and RAL 1012 (yellow) --------------------------------------- Price ex works plus shipping and packaging: on request! --------------------------------------- Options with extra charge -4 swivel castors with PU tread D=150 mm, 2 of which have a stop device instead of 4 plastic swivel castors. Price ex works plus shipping and packaging: on request! - Support and clamping device, pluggable in hollow profile, length 720 mm, can be used for all transport trolleys, to secure the loaded load. Price ex works plus shipping and packaging: on request! - Extension to the left and right for RU-KW1600,RU-KW-2000, RU-KWI-1600, RU-KWI-2000 and all RU-KW-S and RU-KWI-S Price ex works plus shipping and packaging: on request! --------------------------------------- Current surcharge for incalculable price increases in material procurement 6% of the total price. --------------------------------------- Technical information according to the manufacturer - without guarantee!

Datasheet

Request / Contact

Outside profiling machine

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2706 · Outside profiling machine

WEINIG - Univar 10/3 - - gebraucht -

Technical details

Weinig Univar 10/3 folding machine --------------------------------- Machine will be cleaned and chcked before delivery For milling around windows, doors and the like with uneven circumferential profiles. Machine suitable for wood thickness 68 to 92 mm Time required per frame milling, medium size 1.20 x 1.20 m - approx. 2 minutes. The available tool positions are selected using a selector switch on the control panel retrieved. Machine with 3 hydraulically controlled right precision Lifting spindles for holding 3 tool sets, 2 x 95 mm spindle stroke per spindle The spindle stroke takes place in a U-movement, so that the opening is possible for short parts The milling stop remains as small as possible. Spindle stroke horizontally fine Adjustable for both tool positions from the operator side. Central lubrication for the spindle units. The 1. Spindle can be selected in right-left rotation. This spindle dips the last 100 mm of each frame end appropriate synchronization tool into the passing wood. Through this This prevents the tool of the subsequent milling spindle from running in the opposite direction working, causing tearouts. Excavation of the first 7 transport rollers using Footswitch. This shortens the lead time. An additional The support rail also allows large-format frames to be milled around. Continuous, chainless rubber roller feed with extreme short roller spacing. Height adjustment of the feed bar electrically readable. Electrical version according to VDE. Machine including operating tools, but without processing tools tools. Technical data: Working width min. 40 mm Working height min. 30 mm, max. 100 mm 1. Profiling spindle (synchronous and counter-rotation) -------------------------------------------------- -- Motor strength lifting spindle 11.0 kW Spindle speed 6000 rpm Spindle diameter 50 mm Clamping length 285 mm Tool zero flight circle 112 - 140 mm Max. tool - D : 232 mm Spindle stroke vertical 2 x 95 mm for 3 tools Basic position under table 10 mm (adjustable up to 20 mm) Spindle stroke horizontal 80 mm with synchronous automatic immersion 2. Profiling spindle ---------------------- Motor strength lifting spindle 11.0 kW Spindle speed 6000 rpm Spindle diameter 50 mm Clamping length 285 mm Tool zero flight circle 112 - 140 mm Max. tool - D : 232 mm Spindle stroke vertical 2 x 95 mm for 3 tools Basic position under table 10 mm (adjustable up to 20 mm) Spindle stroke horizontal 80 mm 3. Profiling spindle ---------------------- Motor strength lifting spindle 11.0 kW Spindle speed 6000 rpm Spindle diameter 50 mm Clamping length 285 mm Tool zero flight circle 112 - 140 mm Max. tool - D : 232 mm Spindle stroke vertical 2 x 95 mm for 3 tools Basic position under table 10 mm (adjustable up to 20 mm) Spindle stroke horizontal 80 mm 4. Profile spindle - fitting unit on the right ------------------------------------------------- For milling the fitting groove in the milling cycle or for grooving in the longitudinal profile. Pneumatic horizontal movement with Selector switch in the control panel. Motor 2.2 KW Speed 6,000 rpm Spindle diameter 40 mm Clamping height 125 mm, 2 tools Tool flight circle min. 140 mm, max. 180 mm Motor power feed 1.1 kW Feed speed 6 - 12 m/min. Feed rollers - D : 95 mm Feed roller width 50/30 mm Feed roller spacing 100/120 mm -------------------------------- Screen control with 150 programs. 1 program is each 1 individual part and includes 2 end profiles and 1 longitudinal profile. Pro programs are for end processing 20 different profiles can be selected for Longitudinal machining of 40 different profiles 1 can be selected (in turning mode 2). When manufacturing, e.g. a frame, up to 8 different programs (parts) can be saved. The program memory can be organized so that up to 18 frames or sashes with a maximum of 8 parts each can be stored. Manufacturing options: - Individual parts - Double parts - frame by frame - in series - Milling Data entry via keyboard with integrated Operator guidance and error diagnosis. ---------------------------------- Length: 4000mm (Length of frame milling ruler: 4500 mm) Width: 2000mm Height: 2200mm (Technical information according to the manufacturer, no guarantee!)

12.000 €

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6827 · Outside profiling machine

WEINIG - Univar 6 P - - gebraucht -

Technical details

Weinig Univar 6 P In order to sell ---------------------- Operating voltage: 380 volts, 50 periods. For milling around windows, doors and similar with uneven edges Profiles. Arrangement of the aggregates: 1. Synchronous spindle on the right, pneumatically clocked. 2. Profiling spindle on the right 3. Fitting spindle Profiling spindle suitable for holding several tools one on top of the other. Spindle movement pneumatic. The 1 spindle works in synchronization for tear-free milling. Respectively This spindle plunges the last 100 mm of a frame end with the Insert the appropriate tool into the wood to prevent tearing at the frame corners avoid. Machine stands, tables, stops: Machine body made of heavy, torsion-free and vibration-damping elements. Stops on the right in the profiling area made of Pertinax. Before Profiling spindle a split stop with sliding bar for short parts. Additional opening rail for large format frames. Feed system: Continuous, chainless feed equipped with rubber rollers. Blow-off device for feed rollers and table. Spindles, hood: Spindles with high concentricity and dynamically balanced. Extraction hoods designed for the cheapest chip flow. Easiest tool change Quick-opening hood lid. Machine operation, setting aids: Operating the machine from the front. Setting the stops for Tool diameter using mechanical number display. Machine electrics, motors, controls: Electrical design according to DIN VDE 0113 - Electrical equipment from Industrial machines EN 60204 IEC 204-1. Further electrical regulations are not taken into account. Engines dynamically balanced. Control of tool positions via selector switch on the control panel. Tools: Machine equipped with operating tools, but without Editing tools. SPINDLE 1 Synchronous spindle Number of tools: 1 Spindle speed: 6000 rpm Spindle diameter: 50mm Tool clamping length: 120 mm Tool diameter max. (milling): 232 mm Tool zero flight circle: 112-140 mm Basic position under table: 10 mm Motor strength: 4 KW (5.5 KW) SPINDLE 2 Number of tools: 4 Spindle stroke vertical: 3 x 80 mm = 4 tools Can be switched to 2 x 95 mm = 3 tools Spindle speed: 6000 rpm Spindle diameter: 50mm Tool clamping length: 320 mm Feed profiling unit: 8 m/min Feed roller width: 50mm/35mm Feed roller diameter: 95 mm Stop height: 70 mm Working width: min. 30 mm; max. 220 mm Working height: min. 30 mm; max. 100mm Workpiece length without tenon: min. 245 mm Tool diameter max. For zero diameter 112 mm: 210 mm For zero diameter 140 mm: 232 mm Tool diameter max. (milling): 232 mm Tool zero flight circle: 112-140 mm Basic position under table: 10/5 mm Motor strength: Spindle: 11 KW Feed: 1.1 KW Feed profiling unit: continuously 6-12 m/min Feed roller width: 50 mm Feed roller diameter: 95 mm Stop height: 70 mm Working width: min. 30 mm; max. 220 mm Working height: min. 30 mm; max. 100mm Workpiece length without tenon: min. 245 mm Special equipment: 3 Mechanical spindle brake for synchronous spindle, profiling spindle and Additional aggregates SPINDLE 3 1 fitting milling unit, right: for milling the fitting groove in the Milling pass or for grooving in the longitudinal profile. Pneumatic horizontal movement with selector switch in the control panel. Motor power: 2.2 KW Speed: 6000 rpm Spindle diameter: 40mm Clamping height: 125 mm Tool flight circle: min. 140 mm; max. 180 mm Basic position below table level: 10 mm Motor reinforcement for synchronous spindle from 4 KW to 7.5 KW Motor reinforcement for profiling spindle from 5.5 KW to 11 KW Screen controls for 99 window types. 1 type can hold up to 8 different parts contain. Manufacturing options: individual parts, milling. Data entry via Keyboard with integrated operator guidance and error diagnosis. Free-standing control cabinet --------------------------------- (technical data according to manufacturer - no guarantee!)

7.000 €

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6828 · Outside profiling machine

Okoma - UF 2 EG mit Schleifeinheit - - gebraucht -

Technical details

1 OKOMA folding machine model UF 2 EG ------------------------------------- 1. Energy data: - Operating voltage: 3 phases, 380 V, 50 Hz. - Compressed air: Air requirement: 13 NL/min. Operating pressure: 8 bar up. Air: according to Pneurop 6611 2. Profile spindle 1: - Spindle arrangement: right - Power 11 kW - Speed ??7000 rpm - Direction of rotation: synchronous and counter rotation - Spindle diameter 40 mm - Usable length 252 mm - Tool diameter max. 230 mm - U-movement of the profile spindle - Positioning vertically Drive: pneumatic cylinder 120 mm cycle for 2 tool positions Position sensor: limit switch - Positioning horizontally Drive: Pneumatic cylinder forward-back Position sensor: limit switch - Automatic immersion: immersion speed can be regulated for tear-free Fold over - Protective and suction hood with connecting piece 140 mm diameter. 3. Profile spindle 2: - Spindle arrangement: right - Power 11 kW - Speed ??7000 rpm - Direction of rotation: counter rotation - Spindle diameter 50 mm - Usable length 272 mm - Tool diameter max. 230 mm - U-movement of the profile spindle - Positioning vertically Drive: pneumatic cylinder 90 mm cycle for 3 tool positions Position sensor: limit switch - Positioning horizontally Drive: Pneumatic cylinder forward-back Position sensor: limit switch - Protective and suction hood with connecting piece 140 mm diameter. 4. Fitting milling device EG: - Spindle arrangement on the right - Drive: three-phase motor 3 kW - Speed ??6000 rpm - Spindle diameter 30 mm - Usable length 47 mm - Vertical positioning: none - Positioning horizontally Drive: Pneumatic cylinder forward-back Position sensor: limit switch (rear only) - Protective and suction hood with connection piece 80mm diameter 5. Stop: - 1st stop: in front of spindle 1 manual chip removal Quick adjustment via. parallelogram - 2nd stop: between spindles 1 and 2 Chip removal: pneumatically adjustable - 3rd stop: after spindle 2 Fixed stop 6. Grinder with automatic immersion and immersion 7. Feed: - Roller distance from axle to axle 130 mm - Roll diameter 110 mm - Roll width 50 mm - Feed can be swiveled away - with pneumatic travel control 8. Support rail for milling: - Rail length: approx. 3000 mm - Adjustment range forward: approx. 100 - 600 mm 9. Electrical control: - Programmable logic controller: Siemens electronics PC control, 30 programs, 380 V., 50 Hz. - Power section: Siemens S 5 - Non-contact limit switches More pictures on request! --------------------------- (technical data according to manufacturer - no guarantee!)

5.000 €

Datasheet

Request / Contact

Roller conveyer

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

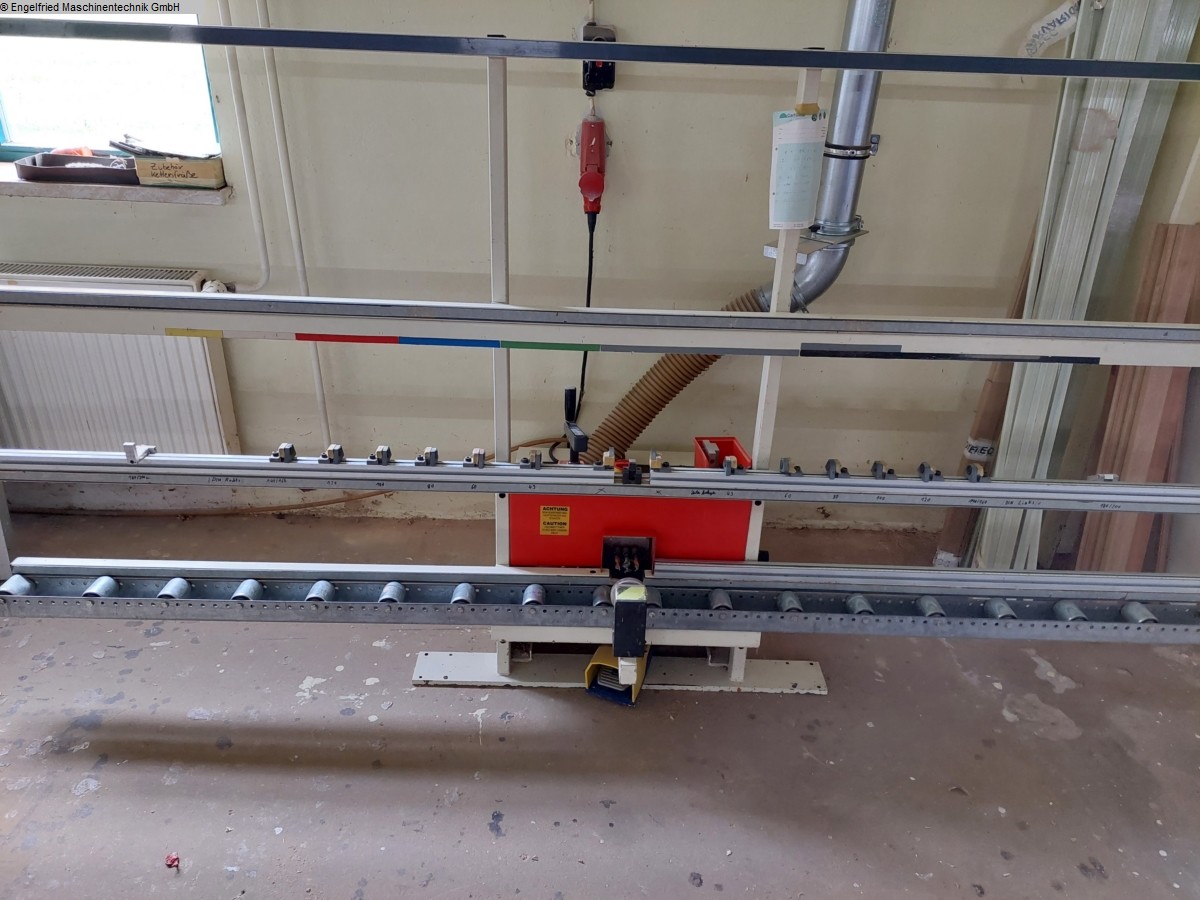

#1305-5918 · Roller conveyer

RUCHSER - RU-RD20 - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-698 · Roller conveyer

RUCHSER - Rollenbahn - - neu -

Technical details

NEW OFFER: 21 m Rollenbahn neu bestehend aus: 7 Einheiten je 3000 mm Länge, Rollenbreite 500 mm, Rollen geteilt , Anschlagseite vertikal mit Röllchen

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6788 · Roller conveyer

RUCHSER - Rollenbahn 4 Stk. - - gebraucht -

Technical details

4 pcs. roller conveyors 2000 x 200 x 1800 mm for internal and external processing

1.000 €

Datasheet

Request / Contact

Sanding machine

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2729 · Sanding machine

LÖWER - Leistomat SD - - neuwertig -

Technical details

Löwer Leistomad SD Window single wood intermediate sanding machine --------------------------------- Machine factory tested by Löwer! Automatic fine grinding machine for wood grinding (smoothing, defibering and Edge breaking) or intermediate sanding of profiled window bars. With soft disc Technology for the visible surfaces as well as automatically safe profile and Width adjustment. - 2 lamella roller units on the side, each 0.37kW, L=100mm, D=200mm - 1 softisc unit Ø=200mm above 0.75kW, - 1 slat roller unit L=200mm above 0.75kW - 1 soft disc unit Ø=200mm below 0.75kW, - 1 lamella roller unit L=200mm below 0.75kW, - 2 lamella roller units on the side, each 0.37kW, L=100mm, D=200mm - Linear guidance of all grinding units via linear ball bearing sets hardened waves - Time-controlled immersion of all lamella roller units directly above the incoming workpiece edges. By immersing it is possible To be able to deliver aggregates deeper into the profiles. - Motorized workpiece thickness adjustment of the machine - variable grinding flap speed via frequency converter to adjust the Grinding intensity using frequency converters (separately for discs, surface rollers and side rollers) - Disc aggregates as soft discs with Velcro fasteners for grinding discs (wood pulp) - Feed via three lower and one upper conveyor belt and spring-loaded Pressure rollers with continuous speed 5-15m/min - Parameters that can be set using the touch panel are workpiece thickness and workpiece width (left side units individually), immersion depth of side units, Spindle speed, feed speed - Saving the parameters as machine programs in program mode - Working in automatic mode with non-contact Workpiece width detection and profile detection as well as automatic Adjustment of the sanding units to the workpiece width and profile shape (Workpiece height is set in advance) - pneumatically clocked driven feed roller, automatic clamping of the workpiece as well as retraction after unit adjustment - Red/green indicator lights to indicate operational readiness - shortest workpiece length 380mm - Transport belt width 200mm - max. workpiece width 180mm - Workpiece height 12-120mm - Suction connection 5 x 100mm diameter - Sensor-controlled tool blow-off directly on the discs - Length (housing) x width x height (mm): 3065x 1500 x 1600, complete length: 3800mm (including inlet roller conveyor with stop for Leistomat SD) - Weight: approx. 1500 kg - Operating voltage 400V, 50Hz, 3P, air connection 6 bar - CE version -------------------------------- Included options: Adjust the machine as follows: - max. workpiece thickness: 160mm - max. workpiece width: 260mm (in the transshipment process, workpieces must be 2x be allowed through) Transport belt width remains at 200mm - Side units with grinding height 120mm instead of 100mm - more powerful engines for side units 0.75kw instead of 0.37 - larger frequency converters for the side units Quick release disc spindle side for quick tool changes for DiscMaster 4TD or CrossMaster 2TD (only for clockwise rotation) Quick release disc tool for Softdisc, Combidisc or Mediumdisc Ø 250mm (only for clockwise rotation) --------------------------------- (Technical description according to the manufacturer - no guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5452 · Sanding machine

QUICKWOOD - QL 4-8 - - neu -

Technical details

Quickwood QL automatische Holzfinish- und Lackzwischenschliffmaschine ------------------------------------------------------------------------------------------------------------- Maschine zur Längsholzbearbeitung - Lose Fasern werden von der Oberfläche entfernt - Erhebliche Reduzierung der Faserbildung nach der Grundierung - Gleichmäßige Aufnahme des Lackes bzw. Beize oder Lasur - Bessere Tiefenwirkung im Holz - Der Lackzwischenschliff wird erheblich reduziert oder entfällt ganz - Stufenlose Einstellungen aller Geschwindigkeiten - Leichter Werkzeugwechsel durch abnehmbare Spindeln - Die Bearbeitung erfolgt vierseitig mit jeweils 2 Spindeln auf einer Schleifseite - Lieferbar auch mit weniger Schleifaggregate je nach Anwendung - Optionale PLC-Steuerung vorgesehen Einsatzmöglichkeiten - Fensterflügel- und - Rahmeneinzelteile - Glasleisten - Profilbretter - Kranzprofile - Verkleidungen - Profilierte Leisten Angebot auf Anfrage! Ausführliche techn. Beschreibung, Bilder und Prospekte nebenstehend als PDF! (techn. Angaben laut Hersteller - ohne Gewähr!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5453 · Sanding machine

QUICKWOOD - ROV 2600 - - neu -

Technical details

Quckwood ROV 2600 vertikale Zwischenschliffmaschine ------------------------------------------------------------------------------- Beidseitiger Lackzwischenschliff von Fensterrahmen, Fensterflügeln und flachen profilierten Haustüren, Möbelteilen am Hängeförderer. - Ruhige Schleifwirkung auf der Oberfläche durch Einsatz von 16 Spindeln pro Schleifseite. - Klemmvorschub für den sicheren Transport der Werkstücke durch die Maschine. - Zentrale Steuerung mit Übernahme- und Übergabeschnittstellen zu anderen Maschinen. - Bürstenplatten für die Stabilisierung der Werkstücke während des Durchlaufs in der Maschine. - Geringerer Platzbedarf durch 2 spiegelbildlich aufgestellte Maschinenhälften. - Hohe Werkzeugstandzeit. Angebot auf Anfrage! Ausführliche techn. Beschreibung, Bilder und Prospekte nebenstehend als PDF! (techn. Angaben laut Hersteller - ohne Gewähr!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5580 · Sanding machine

LÖWER - DSM 2000 - - neu -

Technical details

LÖWER double-sided grinding machine DSM 2000 --------------------------------- Double-sided single wood sander for sanding Solid wood such as window wood etc. Stable top quality Guide with long casting tables, brushing and finishing equipment and conveyor belt feed. Suitable for high continuous loads even with higher chip removals. - Staggered sanding and finishing units at the top and bottom - Directly driven rubberized grinding rollers for slip-free power transmission - Combined grinding via roller and shoe for high chip removal at the same time flat intervention zone - Maintenance and wear-free CERMET-coated sanding shoes with very good thermal conductivity and absolute Dimensional accuracy - External cooling of the grinding zones for cooler grinding and higher grinding Grinding belt service life - Forced pneumatically controlled sanding belt oscillation - effective sanding dust extraction directly on the sanding rollers Airborne dust extraction on the tension rollers - Integrated brushing and finishing device with large sanding dust extraction - Motorized grinding thickness adjustment via precision threaded spindles and large-sized linear ball bearing sets on hardened and ground precision shafts with dust and dirt protection - Adjustment of the chip removal at the bottom using a precision threaded spindle Dimension display via scale ring (resolution 0.1mm) - Sanding belt tension via pneumatic cylinders with constant clamping pressure - Sanding belt change with pneumatic belt relaxation in seconds - Adjustment of the sanding belt run when changing the belt - electro-pneumatic compressed air monitoring - Run-in protection via contact roller for workpieces that are too thick - Workpiece transport via calibrated non-slip and non-stick conveyor belts over heavy, 1000mm long cast tables with a finely planed surface and Spring-loaded pressure rollers with fine adjustment - Cardan shaft drive for smooth and even workpiece transport - Feed gear motor with three different feed speeds for quick adaptation to different types of wood - all motors electrically protected - Ergonomically arranged controls on the workpiece inlet side - automatic workpiece thickness scanning (no previous measurement necessary) - Digital thickness display (resolution 0.1mm) with modern magnetic tape system Technical data: - Sanding belt speed: 22 m/s - Sanding belt length: 1800mm - Sanding belt width: 200mm - Working width: 190mm - Grinding thickness: 2-180mm - two brake motors for drive: 5.5 kW - Feed motor: 1.0 kW - Feed speed: 6, 11 and 16 m/min. - automatic height adjustment: 0.37 kW - two brush units with fiber brushes D 120 x 200mm at 0.37 kW - Suction nozzle: 2 x 120mm and 2 x 150mm - Pneumatic connection 6 bar - Working height: 850mm - Length: 2105mm - Length with control panel 2490mm - Width: 880mm - Height: 1910mm - Weight: approx. 1500 kg - Operating voltage: 400 volts, 50 Hz, 3P - CE version -------------------------------------------------- ---------------------- Basic price of the machine on request! -------------------------------------------------- ---------------------- Special accessories with surcharge: continuous feed 4-20 m/min. for speed adjustment to the previous machine Price on request Workpiece blow-off - using nozzles from above and below at the machine outlet arranged, pneumatically controlled Price on request Sanding belt blowout - via nozzles directly on the radii of the tension rollers inside arranged in the suction system and can be switched on separately Price on request Lateral displacement of the entire machine - adjustable 50-100mm oscillating for more even Utilization of sanding belts, finishing tools and Transport system, geared motor 0.37kW (not available in conjunction with disc/softdisc unit) Price on request Transport freewheel device - when linked with little distance to the previous machine Price on request External start impulse of the machine - via a button including control option via external PLC control (when linked in a production line) Price on request DUPLO control - additional control panel for attachment to a upstream machine with the following functions: - Start button - Emergency stop switch - Height adjustment up, down and 1/10 down - Digital strength display - shielded special cable, (max. 20m) Price on request -------------------------------- (technical information according to the manufacturer - no guarantee!) All prices quoted are net. plus statutory VAT

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6006 · Sanding machine

LÖWER - MiniSpin N - - neu -

Technical details

Loewer edge finishing machine MiniSpin N Machines for finishing and fine sanding of Edges and profiles with a grinding spindle horizontal or vertical. Motor 0,75 KW Spindle in vertical position for machining edges Pivoted spindle in horizontal position, laterally etc. for processing longer profile bars or Conjunction with a combined grinding head for grinding of edges with a grinding disc blades Grinding head swiveling + / - 20 ° for editing oblique lines Working height / width 150 mm max. Diameter roller / brush <300 mm Frequency converter for stepless adjustment of the Spindle speed 200-800 rpm Table size 400 x 800 mm two directions of rotation selectable Operating voltage 110/240 V 50/60 Hz Exhaust connection D = 100 mm Weight 100 kg including grooved body D = 180, L = 150 placement with SmartFlex grinding blades CE - execution (technical details according to manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5088 · Sanding machine

LÖWER - DSM 2004 - - neu -

Technical details

LÖWER-DoubleSander Solid DSM 2004 ---------------------------------- Double-sided four-belt single wood sander for Sanding solid wood such as window frames etc. Highly stable top design with innovative details. Suitable for high continuous loads even with higher chip removals. - sanding units arranged one after the other for pre-grinding, Fine sanding and finishing sanding, each from above and below 1. Belt sanding unit with heavy steel roller 2. Belt sanding unit with rubberized roller and shoe 3. Finishing unit with fiber brush - Directly driven grinding rollers for slip-free Power transmission - maintenance and wear-free CERMET-coated grinding wheels shoes with very good thermal conductivity and absolute Dimensional accuracy - External cooling of the grinding zones for cooler grinding and longer sanding belt service life - force-guided pneumatically controlled sanding belt oscillation - effective sanding dust extraction directly on the Grinding rollers - Airborne dust extraction on the tension rollers - Integrated brushing and finishing device with large Grinding dust extraction - motorized grinding thickness adjustment via precision threaded spindles and large-sized linear ball screws bearing sets on hardened and ground precision shafts with dust and dirt protection - Adjustment of the chip removal at the bottom via precision Threaded spindle with dimension display via scale ring (Resolution 0.1mm) - Sanding belt tension via pneumatic cylinder constant clamping pressure - Sanding belt change with pneumatic belt relaxation Within seconds - Adjustment option for the sanding belt run Band change - electro-pneumatic compressed air monitoring - Anti-running protection via contact roller if it is too thick workpieces - Workpiece transport via calibrated non-slip and non-stick fixed conveyor belts over heavy, cast tables Finely planed surface and spring-loaded pressure rollers with fine adjustment - Cardan shaft drive for smooth and consistent Workpiece transport - Feed gear motor with stepless speed 4-20 m/min - all motors electrically protected - ergonomically arranged controls - digital thickness display (resolution 0.1mm) with modern Magnetic tape system Technical data: - Sanding belt speed 22 m/s - Sanding belt length 1800mm - Sanding belt width 200mm - Working width 190mm - Grinding thickness 2-180mm - four brake motors for 5.5 kW drive - Feed motor 1.5 kW - Feed speed 4-20 m/min. - automatic height adjustment 0.37 kW - two brush units with fiber brushes D 120 x 200mm at 0.37 kW - Suction nozzle 2 x 180mm 2 x 120mm - Extraction air speed 20 m/s - Pneumatic connection 6 bar - Working height 870mm - Length (with soft disc 2740mm) 2600mm - Length with control panel (with soft disc 3035mm) 2985mm - Width 880mm - Height 1910mm - Weight approx. 3300 kg - Operating voltage 400 volts, 50 Hz, 3P - CE version --------------------------------- Price of the above machine on request! --------------------------------- Special accessories with additional charge: Workpiece blow-off - using nozzles from above and below at the machine outlet arranged, pneumatically controlled 4-belt sanding belt blowout via nozzles directly on the radii of the tension rollers inside the suction arranged, timer controlled on/off 5 seconds each, can be switched on separately Disc unit for defibering - two grinding flap discs with a diameter of 200mm (max. grinding width 180mm) - Adjustable laterally and in delivery - including frequency converter for stepless speed control instead of the standard brushing and finishing facility Soft disc aggregate a soft disc each at the top and bottom for the intensive defibering cross-section with fine grain size - Discs with a diameter of 200mm - Manually adjustable laterally and in delivery - sensor-controlled automatic immersion - Continuous speed control via frequency converter - Boundary ruler min. workpiece thickness 20mm instead of the standard brushing and finishing facility Roller finish package - two grooved roller base bodies with grinding lamellas equipped - Total diameter approx. 180mm - including frequency converter for stepless Speed ??control instead of the standard brushing and finishing facility Lateral displacement of the entire machine - adjustable 50-100mm oscillating for more even Utilization of sanding belts, finishing tools and Transport system, geared motor 0.37kW (not available in conjunction with disc/softdisc unit) Transport freewheel device - when linked with little distance to the previous machine External start impulse of the machine via a button Control option via an external PLC control (at chaining in production line) DUPLO control - additional control panel for attachment to a upstream machine with the following functions: - Start button - Emergency stop switch - Height adjustment up, down and 1/10 down - Digital strength display - shielded special cable, (max. 20m) PLC Power Panel package for DSM instead of standard contactor control - B&R PLC touch panel for operation and display - Parameters that can be set using the touch panel are workpiece thickness, Grinding units on/off, feed on/off, Feed speed, belt blow-off on/off (if available), disc motor (if available) - Saving the parameters as machine programs - Ethernet interface (UDP protocol) - Manual/automatic operation selector switch Road connection, preparation for master computer control Automatic workpiece thickness scanning (no prior measurement necessary) Set of SmartFlex sanding flaps for DSM with sanding flap discs consisting of: 60 strips M 35 / 50 Set of SmartFlex sanding flaps for DSM with flap rollers consisting of: 48 strips M 55 / 200 Sandpaper disc VB for soft disc D=200mm grit 280 with velor backing (Velcro), pack of 100. ---------------------------------- Prices of the above-mentioned special accessories on request! ---------------------------------- (technical information according to the manufacturer - no guarantee!) All prices quoted are net. plus statutory VAT

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5343 · Sanding machine

MB - Roba Twin Flat -Video- - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6199 · Sanding machine

LÖWER - DoubleMaster DSM 2000 - - neu -

Technical details

LÖWER - DoubleMaster DSM 2000 DB ------------------------------------------------- Double-sided single wood sander with additional Transverse brush sanding unit (discs) and Longitudinal brush sanding unit (roller) for sanding Solid wood such as B. window wood etc. Stable top version with long cast tables and Conveyor belt feed. Suitable for high continuous loads even with higher chip removals. 1. Belt sanding unit with CERMET sanding shoe pre-sanding 2. Disc aggregate cross grinding for defibering 3. Rolling aggregate longitudinal grinding for directional finish Direction of growth - Staggered sanding and finishing units at the top and below - directly driven rubberized sanding rollers for slip-proof free power transmission - Combined grinding via roller and shoe for high chip removal with a flat intervention zone at the same time - maintenance and wear-free CERMET-coated grinding wheels shoes with very good thermal conductivity and absolute Dimensional accuracy - External cooling of the grinding zones for cooler grinding and longer sanding belt service life - force-guided pneumatically controlled sanding belt oscillation - effective sanding dust extraction directly on the Grinding rollers - Airborne dust extraction on the tension rollers - integrated brush grinding device (transverse and Longitudinal) with sanding dust extraction - motorized grinding thickness adjustment via precision threaded spindles and large-sized linear ball screws bearing sets on hardened and ground precision shafts with dust and dirt protection - Adjustment of the chip removal at the bottom via precision Threaded spindle with dimension display via scale ring (Resolution 0.1mm) - Sanding belt tension via pneumatic cylinder constant clamping pressure - Sanding belt change with pneumatic belt relaxation Within seconds - Adjustment option for the sanding belt run Band change - electro-pneumatic compressed air monitoring - Anti-running protection via contact roller if it is too thick workpieces - Workpiece transport via calibrated non-slip and non-stick fixed conveyor belts over heavy, 1000mm long cast iron tables with a finely planed surface and spring-loaded Pressure rollers with fine adjustment - Cardan shaft drive for smooth and consistent Workpiece transport - Feed gear motor infinitely variable for quick adaptation to different types of wood - all motors electrically protected - ergonomically arranged controls on the Workpiece inlet side - digital thickness display (resolution 0.1mm) with modern Magnetic tape system Technical data: - Sanding belt speed 22 m/s - Sanding belt length 1800mm - Sanding belt width 200mm - Working width 190mm - Grinding thickness 2-180mm - two brake motors for 5.5 kW drive - Feed motor 1.0 kW - Feed speed 4-20m/min. - automatic height adjustment 0.37 kW - Brush sanding units Disc D=max. 200mm Roller D=max. 270mm - Suction nozzles 2 x 120mm and 2 x 180mm - Pneumatic connection 6 bar - Working height 870mm External dimensions: - Length 2600mm - Length with wheels 2985mm - Width 880mm - Height 1910mm - Weight approx. 1500 kg - Operating voltage 400 volts, 50 Hz, 3P - CE version -------------------------------- Price of the above machine on request! -------------------------------- Special accessories with additional charge: Workpiece blow-off - using nozzles from above and below at the machine outlet arranged, pneumatically controlled Sanding belt blowout via nozzles directly on the radii of the tension rollers inside the suction arranged, timer controlled on/off 5 seconds each, can be switched on separately Soft disc unit instead of grinding flap disc unit top and bottom for more aggressive cross and fine sanding including sensor-controlled automatic immersion Automatic workpiece thickness scanning no prior measurement necessary) Set of SmartFlex sanding flaps for DSM with flap disc consisting of: 60 strips M 35 / 50 Set of SmartFlex sanding flaps for DSM with flap roller consisting of: 48 strips M 55 / 200 Sandpaper disc VB for soft disc D=200mm grit 280 with velor backing (Velcro), pack of 100. Prices of the above-mentioned special accessories on request! -------------------------------- (technical data according to manufacturer - no guarantee!)

Datasheet

Request / Contact

Engelfried Maschinentechnik GmbH

Elisabethenstr. 41

Contact Trader

Engelfried Maschinentechnik GmbH

Elisabethenstr. 41

73432 - Aalen

Deutschland

(0049)07361-98660

(0049)07361-986640

info@engelfried.com

www.engelfried.com

Contact person:

Elisabethenstr. 41

73432 - Aalen

Deutschland

(0049)07361-98660

(0049)07361-986640

info@engelfried.com

www.engelfried.com

Contact person:

Machine category

Abrichthobelmaschine · Absauganlage · Band- und Profilschleifmaschine · Bandsäge · Beschlagcenter · Bohr- und Dübeleintreibmaschine · Breitbandschleifmaschine · Clipsetzer fuer Holz-Alufenster · CNC-Bearbeitungszentrum · CNC-Bearbeitungszentrum Fenster u. Türen · Dickenhobelmaschine · Doppelgehrungssäge · Dreh- und Kipptisch · Druckbalkensäge · Ecklager- und Olivenbohrmaschine · Einzelholzschleifmaschine · Entstauber · Fensteranlage · Fensterlackieranlage · Fensterwerkzeuge · Fertigungslinie · Formatkreissäge · Fräsmaschine · Furnierklebegerät · Furnierpresse · Füge- und Feinschnittmaschine · Glasleistensäge · Kantenschleifmaschine · Kapp- und Gehrungssäge · Keilzinkenanlage · Klammergeräte · Kombinierte Abricht- und Dickenhobelmasc · Kommissionswagen · Kompressor · Kreuzsprossenfräse · Lamellierpresse · Leimauftragsmaschine · Leimgerät · Längskreissäge · Längsschnittkreissäge · Minizinkenpresse · Montagestation · Olivenbohrmaschine · Optimierungskappsäge · Plattensägen vertikal · Profilwagen · Rahmen- und Langlochbohrmaschine · Rahmenpresse · Rollenbahn · Rundbogenfräsgeräte · Schleifmaschine · Schwenkfräsmaschine · Transportanlage · Transportwagen · Umfälzautomat · Untertischkappsäge · Verglasungs- und Kontrollpresse · Verleimstern · Vierseitenhobelmaschine · Werkstückrückführung · Werkzeug-Reinigungsgeräte · Zapfenschneid- und Schlitzmaschine · Zerspanen ·