coil line

Machinelist: coil line

coil line

- Ambold Pressen GmbH

- Sommeritzer Straße 43

- 04626 Schmölln

- Deutschland

-

+49 (0)3449183314

+49 (0)3449123492 -

info@ambold-pressen.de

www.ambold-pressen.de

#1010-531 · coil line

1SCHLEICHER/GSW - - - unbekannt -

Technical details

CNC roll feed, Make GSW, Type WVE 400/160 - weight 50/80 kg Straightener, 7 rolls, Make. Schleicher, Type RM 6-95/160 - band width 300 mm - band thickness 2 – 4 mm - cross cut 1200 mm² - voltage 220/380 V 50 Hz - total power requirement 3,1 kW coiler with press roll, Make Schleicher, Type H-3 - Coil weight 3 t - Band width 400 mm - voltage 220/380 V 50 Hz - total power requirement 3,92 kW

- VÖGTLE SERVICE GMBH

- Friedhofstr. 115

- 73054 Eislingen

- Deutschland

-

+49 71 61 99 73- 0

+49 71 61 99 73- 13 -

Thomas.Ruckh@voegtle.de

www.voegtle.de

#1050-103046 · coil line

GSW - SHR 5000 / VCRL 650 - - 2000 - konventionell

Technical details

Feeder-straightening machine VCRL 650 (year of manufacture1994 / overhauled 2001) with infinitely variable drive, motoric height adjustment, hydraulic alligator opening, intermittent lifting Decoiler SHR 5000 (year of manufacture 2000) with hydraulic expansion, snubber roll

- VÖGTLE SERVICE GMBH

- Friedhofstr. 115

- 73054 Eislingen

- Deutschland

-

+49 71 61 99 73- 0

+49 71 61 99 73- 13 -

Thomas.Ruckh@voegtle.de

www.voegtle.de

#1050-083096 · coil line

DREHER - 2352 B-FPS / SC 12-FQ - - 1997 - Siemens S 5

Technical details

Universal straightening machine SC 12-FQ with infinitely variable drive double decoiler 2352 B-FPS WITHOUT drive, with hydraulic expansion, pneumatic lag brake electronic roll feed WAV-RDS-2Z, modell 1082 B with AC-Servomotor, pneumatic intermediate lifting of the rolls

- VÖGTLE SERVICE GMBH

- Friedhofstr. 115

- 73054 Eislingen

- Deutschland

-

+49 71 61 99 73- 0

+49 71 61 99 73- 13 -

Thomas.Ruckh@voegtle.de

www.voegtle.de

#1050-194014V · coil line

HENSEL - BRMS 4/500/10 / BSH 3-500 / - - 1996 - konventionell

Technical details

Straightening machine HENSEL BRMS 4/500/10 with infinitely variable drive Decoiler HENSEL BSH 3-500 mith motor for fix speed, auxiliary drive (declutchable), pneumatic snubber roll Electronic roll feed HENSEL EVX 500 with hydraulic intermediate lifting of the rolls Material thickness of feeder approx. 0,2 - 5,0 mm with coil loop control via light guard

- SKM Industriemaschinen

- Röntgenstr. 3

- 89264 Weißenhorn

- Deutschland

-

+49 (0) 7309 954 986 0

+49 (0) 7309 954 986 1 -

info@skm-maschinen.de

www.skm-maschinen.de

#2032-1740 · coil line

DREHER - 1676 AV-RA2 / 2370 B - - 1995 -

Technical details

Coil turner 2370 B Load capacity 1.5 ton. Bandwidth 300 mm Coil inner diameter: 400 - 500 mm Arm length per arm: 670 mm Dimensions: depth 1,230 mm, housing height 1,100 mm, width 1,700 mm Weight: 760 kg. Straightener Dreher 1676 AV-RA2 Material width: 200 mm Material thickness: 08 - 4.2 mm Number of straightening rollers: 7 Number of pull rollers: 4 Straightening rollers diameter: 80 mm Would be down by a running press Documents circuit diagrams, operating instructions etc. available

- VÖGTLE SERVICE GMBH

- Friedhofstr. 115

- 73054 Eislingen

- Deutschland

-

+49 71 61 99 73- 0

+49 71 61 99 73- 13 -

Thomas.Ruckh@voegtle.de

www.voegtle.de

#1050-233027 · coil line

KOHLER / WEINGARTEN - 50.650/9-7500.1 / WEP 65 - - 1995 - konventionell

Technical details

Straightening machine KOHLER 50.650/9 with infinitely variable drive, driven straightening rolls, hardchromium-plated rolls, motoric adjustment of the roller cassette Decoiler KOHLER 7500.1 with auxiliary drive, hydraulic centralized expansion, hydraulic snubber roll, attachment jaws for expansion of the inner diameter to approx. 580 - 630 mm, motoric lateral movement, hydraulic lifting table Servo roll feed WEINGARTEN WEP 65 coil loop control via light guard

- VÖGTLE SERVICE GMBH

- Friedhofstr. 115

- 73054 Eislingen

- Deutschland

-

+49 71 61 99 73- 0

+49 71 61 99 73- 13 -

Thomas.Ruckh@voegtle.de

www.voegtle.de

#1050-163021A · coil line

NORMATIC - DY 500 X3000 - - 1994 - konventionell

Technical details

Straightening machine RYD 40 x 500 hydraulic inlet guide Decoiler DY 500 x 3000 with hydraulic expansion, hydraulic coil lifting device elektronic roll feed AESL 500-2,8 can be offered without or with putting into operation in given condition

- Goedicke Werkzeugmaschinenhandels GmbH

- Heinz-Nixdorf-Str. 2

- 74172 Neckarsulm

- Deutschland

-

+49-(0) 7132–999 360

+49-(0) 7132–999 3690 -

info@goedicke.com

www.goedicke.com

#1048-729197 · coil line

AMTEC - PBS 24/24 - - 1994 -

Technical details

Technical description : This BLANK COATING SYSTEM 'PBS 24/24' serves as a complete surface or partial application of lubricants on rectangular or formed blanks. The coating process is being carried out separately for top side or bottom side via a valve row, whereby the blanks travel in between with constant speed. The effluence rate of the spray valves for top and bottom side can be adjusted individually. A heating device facilitates the processing with high viscosity lubricants. - Year of Manufacture: December 1994 - Max. Blank length: 1800mm - Max. Blank width: 2500mm - Medium emulsion, oil, grease

Datasheet

Request / Contact

- VÖGTLE SERVICE GMBH

- Friedhofstr. 115

- 73054 Eislingen

- Deutschland

-

+49 71 61 99 73- 0

+49 71 61 99 73- 13 -

Thomas.Ruckh@voegtle.de

www.voegtle.de

#1050-183063A · coil line

DREHER - 1676 E/RDS / 2380 FM-FPS - - 1994 - konventionell

Technical details

Feeder-straightening machine DREHER 1676 E/RDS Modell 1529/4 with infinitely variable drive Decoiler DREHER 2380 FM-FPS Modell 891/5 motoric driven. with pneumatic lag brake, manual centralized expansion, pneumatic snubber roll coil loop control Ultrasonic

- Maschinen Schwartpaul GmbH

- Am Wasserwerk 1

- 58840 Plettenberg

- Deutschland

-

+49 (0)2391-95960

+49 (0)2391-959620 -

info@maschinen-schwartpaul.de

www.maschinen-schwartpaul.de

#2020-15596 · coil line

TEAP - AMDC150+RM - - 1993 -

Technical details

Datasheet

Request / Contact

- VÖGTLE SERVICE GMBH

- Friedhofstr. 115

- 73054 Eislingen

- Deutschland

-

+49 71 61 99 73- 0

+49 71 61 99 73- 13 -

Thomas.Ruckh@voegtle.de

www.voegtle.de

#1050-133013 · coil line

DIMECO - 1676 EV / 2382 FFPS - - 1990 - konventionell

Technical details

Straightening machine Dimeco, 1676 EV with inlet table andpre-shaping roll, hydraulic loading bridge Double decoiler Dimeco 2382 FFPS with pneumatic lag brake, hydraulic expansion, hydraulic snubber roll, coil loading device elektronic roll feed Microfeed kann ohne in Betrieb nehmen oder alternativ mit neuer Steuerung Siemens S 7-1500 F angeboten werden can only be offered without putting into operation - video at seller's site before dismantling available

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03639 · coil line

SCHLEICHER - - - -

Technical details

- Goedicke Werkzeugmaschinenhandels GmbH

- Heinz-Nixdorf-Str. 2

- 74172 Neckarsulm

- Deutschland

-

+49-(0) 7132–999 360

+49-(0) 7132–999 3690 -

info@goedicke.com

www.goedicke.com

#1048-739033 · coil line

SCHARF WESTFALIA - - - -

Technical details

Technical description : Blank Pallet Turnover Device / Blank Handlling (needs retrofit)

Datasheet

Request / Contact

Plate Shear - Mechanical

- Plum & Partner Werkzeugmaschinen GmbH

- Winkelstraße 32

- 32257 Bünde

- Deutschland

-

+49 05223 574444

+49 5223188330 -

info@plum-maschinen.de

www.plum-maschinen.de

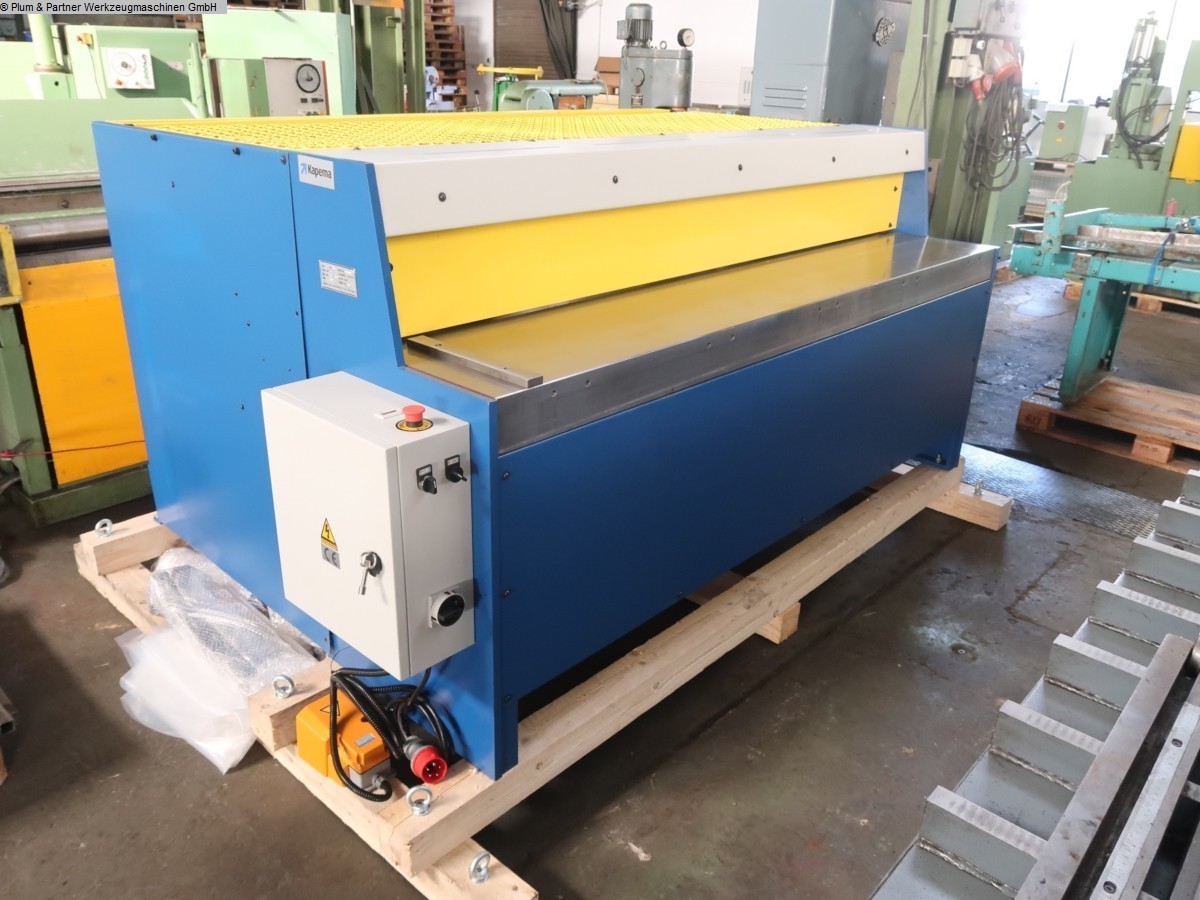

#1082-08037 · Plate Shear - Mechanical

KAPEMA - SMP 20-20 - - Fabrikneu / new -

Technical details

The new motor guillotine type SMP is a well dimensioned machine with all-welded link guides. The drive takes place with a Standard geared brake motor via a chain connection to the main axle. the Knives are of the highest quality. The optimal cutting angle secures the Together with the rubber-covered blank holder perfect cuts. Bearings and guides are maintenance and lubrication-free. Standard equipment: • Back gauge 665 with mm scale. • cutting edge lighting. • Section counter. • Table extensions 600 mm. • Right angle stop, left. • Movable 24 V foot switch with emergency stop. • Motor protection switch and emergency stop. • 2 cutting edges per knife. • Rear protective grille, warranty = 12 months for single-shift operation. Other models: 1275 x 3mm, 1250 x 4mm, 2050 x 2mm Machine dealer with own stock of 1600 m².

Datasheet

Request / Contact

- Plum & Partner Werkzeugmaschinen GmbH

- Winkelstraße 32

- 32257 Bünde

- Deutschland

-

+49 05223 574444

+49 5223188330 -

info@plum-maschinen.de

www.plum-maschinen.de

#1082-08408 · Plate Shear - Mechanical

KAPEMA - SMP 12-30 - - Fabrikneu / new -

Technical details

The guillotine shears type SMP is a well-dimensioned machine with all-welded gate guides. The drive takes place with a standard geared brake motor via a chain connection to the main axis. The knives are of the highest quality. The optimal cutting angle ensures together with the rubber-coated sheet metal holder, perfect cuts. Bearings and guides are maintenance-free and lubrication-free. Standard equipment: • Back gauge 635 with mm scale. • Cutting line lighting. • Section counter. • Table extensions 600 mm. • Right-angled stop, left. • Movable 24 V foot switch with emergency stop. • Motor protection switch and emergency stop. • 2 cutting edges per knife. • rear photocell. Pre-freight to our stock + packaging 270, -. Machine dealer with own stock of 1600 m².

Datasheet

Request / Contact

- Plum & Partner Werkzeugmaschinen GmbH

- Winkelstraße 32

- 32257 Bünde

- Deutschland

-

+49 05223 574444

+49 5223188330 -

info@plum-maschinen.de

www.plum-maschinen.de

#1082-08417 · Plate Shear - Mechanical

KAPEMA - SMP 20-30 - - Fabrikneu / new -

Technical details

The new motor guillotine type SMP is a well dimensioned machine with all-welded link guides. The drive takes place with a Standard geared brake motor via a chain connection to the main axle. the Knives are of the highest quality. The optimal cutting angle secures the Together with the rubber-covered blank holder perfect cuts. Bearings and guides are maintenance and lubrication-free. Standard equipment: • Back gauge 665 with mm scale. • cutting edge lighting. • Section counter. • Table extensions 600 mm. • Right angle stop, left. • Movable 24 V foot switch with emergency stop. • Motor protection switch and emergency stop. • 2 cutting edges per knife. • Rear protective grille, warranty = 12 months for single-shift operation. Other models: 1275 x 3mm, 1250 x 4mm, 2050 x 2mm Machine dealer with own stock of 1600 m².

Datasheet

Request / Contact

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-01210 · Plate Shear - Mechanical

RFR - MS/24 - - ca. 1960 -

Technical details

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-22062 · Plate Shear - Mechanical

RAS - 53.60 - - 380/6 -

Technical details

Datasheet

Request / Contact

- SKM Industriemaschinen

- Röntgenstr. 3

- 89264 Weißenhorn

- Deutschland

-

+49 (0) 7309 954 986 0

+49 (0) 7309 954 986 1 -

info@skm-maschinen.de

www.skm-maschinen.de

#2032-1144 · Plate Shear - Mechanical

OSTAS - RGM 1550 x 3 - - 2019 -

Technical details

Producer: OSTAS Type: RGM 1050 x 3 YOM: new Max. Shearing Length: 1.050 mm Shearing Capacity: 3 mm Shearing Angle: 2°30' Strokes Per Minute: 35 d/d Motor Power: 3 kW Table Width: 510 mm Table Height: 820 mm Rear Gauge Distance: 500 mm Dimensions of the machine (LxWxH): 1.640 x 2.060 x 1.210 mm Weight: ca. 1.100 kg Additional information: • Manual backgauge with 500 mm stroke • Squaring arm with T-slot, stopper and ruler • Foot pedal • Front sheet holding arms • Cutting line lighting • Protection Cages optional: • Cutting unit counter • Motorised backgauge with 500 mm stroke • Backgauge with NC control • Pneumatic Sheet Support System • Optical security bar • 0-180° angle cutting

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-3320042 · Plate Shear - Mechanical

METALLKRAFT - FTBS 1050-10 - - 2017 -

Technical details

- Frech GmbH

- Werderstr. 82

- 74889 Sinsheim

- Deutschland

-

0049-7261-1011

0049-7261-63966 -

info@frech-maschinen.de

www.frech-maschinen.de

#1073-94086 · Plate Shear - Mechanical

DURMA - MS 2504 - - 2012 -

Technical details

** Current new price with special accessories ~ 33.000 euros ** from a maintenance workshop / good condition (!!) Furnishing: - robust / powerful mechanical guillotine shears - electric backgauge, with ball screws - with DURMA NC control - model D-Touch 7 * Control unit with touchscreen function * 128 MB internal memory (programming possible) * Multilingual (English, Turkish, German) * INCH/metric conversion - manual cutting gap adjustment, from the front * analogue display of the material thickness - 1x extra long side stop 2.000 mm, with support foot & T-slot - 2x support arms - Ball casters in the support table - free-moving footswitch - rear protective device (light barrier) - original operating instructions (machine + control) Special accessories included : - Pneumatic sheet metal holding device, for thin sheet metal blanks - 1x extra long side stop, with support foot - 1x box with spare knife

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9325259 · Plate Shear - Mechanical

DURMA - MS 2504 - - 2012 -

Technical details

** Current new price with special accessories ~ 33.000 euros ** from a maintenance workshop / good condition (!!) Furnishing: - robust / powerful mechanical guillotine shears - electric backgauge, with ball screws - with DURMA NC control - model D-Touch 7 * Control unit with touchscreen function * 128 MB internal memory (programming possible) * Multilingual (English, Turkish, German) * INCH/metric conversion - manual cutting gap adjustment, from the front * analogue display of the material thickness - 1x extra long side stop 2.000 mm, with support foot & T-slot - 2x support arms - Ball casters in the support table - free-moving footswitch - rear protective device (light barrier) - original operating instructions (machine + control) Special accessories included : - Pneumatic sheet metal holding device, for thin sheet metal blanks - 1x extra long side stop, with support foot - 1x box with spare knife

Datasheet

Request / Contact

- Frech GmbH

- Werderstr. 82

- 74889 Sinsheim

- Deutschland

-

0049-7261-1011

0049-7261-63966 -

info@frech-maschinen.de

www.frech-maschinen.de

#1073-94181 · Plate Shear - Mechanical

HM - NWKS 2000/3 - - 2010 - DIGI

Technical details

** Machine from a maintenance workshop ** maintained condition (!!) Furnishing: - robust electro-mechanical sheet metal shears - Machine body in a closed design as an all-steel welded construction - heavy / robust drive motor (5.5 KW) - electro-motorized backgauge, including digital control unit * Adjustment range max. 1.000 mm * Input of target / actual value possible - manual cutting gap adjustment, adjustable from the front - 1x table side stop - Ball rollers in the support table - 1x freely movable foot switch, including EMERGENCY stop button - front finger protection - original instruction manual

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9325336 · Plate Shear - Mechanical

HM - NWKS 2000/3 - - 2010 - DIGI

Technical details

** Machine from a maintenance workshop ** maintained condition (!!) Furnishing: - robust electro-mechanical sheet metal shears - Machine body in a closed design as an all-steel welded construction - heavy / robust drive motor (5.5 KW) - electro-motorized backgauge, including digital control unit * Adjustment range max. 1.000 mm * Input of target / actual value possible - manual cutting gap adjustment, adjustable from the front - 1x table side stop - Ball rollers in the support table - 1x freely movable foot switch, including EMERGENCY stop button - front finger protection - original instruction manual * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9325336

Datasheet

Request / Contact

TOP Manufacturer:

DREHER - 1SCHLEICHER/GSW - HENSEL - AMTEC - KOHLER / WEINGARTEN - TEAP - SCHARF WESTFALIA - NORMATIC - GSW - SCHLEICHER -