Double Flank Gear Testing Machine

Machinelist: Double Flank Gear Testing Machine

Bevel Gear Generator - Spiral

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24006 · Bevel Gear Generator - Spiral

HURTH-MODUL - KF 250 B - - 1998 - Siemens Sinumerik 840 C

Technical details

incl. suction

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-16040 · Bevel Gear Generator - Spiral

KLINGELNBERG - KNC 25 P - - 1997 -

Technical details

max. wheel diameter mm gear width mm max. module 6 min. module 1.5 max. workpiece diameter 275 mm tooth width max. 5.5 mm spiral angle 0 - 60 ° number of teeth 5 - 120 transmission ratio min. 1:1 transmission ratio max. 1:10 milling drive motor 20 kW workpiece drive 14.5 kW total power requirement 62 kVA weight of the machine ca. 12 t dimensions of the machine ca. 4,7 x 4,387 x 2,45 m Tool spindle (D-axis) - workpiece spindle speed (infinitely) 60 to 350 [...] Tool positioning axis (E-axis) - swivel range 0 to 360° - swivel speed max. 19.5°/s Workpiece spindle (B-axis) - mounting diameter outer cone (1: 4) 140 mm - standard internal cone (1:20) 99.218 mm - workpiece spindle speed max. 300 [...] - workpiece spindle passage 90 mm Workpiece positioning axis (Y-axis) - travel 870 mm - speed max. 4.5 m/min Roller rotation axis (A-axis) - swivel range 315° - swivel speed max. 40°/s Axis intersection (Z-axis) - travel range max. +/- 50 mm - speed max. 0.657 m/min Workpiece swivel axis (C-axis) - swivel range -8.5 to 98° - swivel speed max. 21.5 °/s Milling depth axis (X-axis) - travel from -25 to 640 mm - max. speed 6 m/min Machinen distance (V-axis) - travel 150 mm - speed max. 1.6 m/min

Datasheet

Request / Contact

- Leyendecker & Hollmann GmbH

- Giesenheide 18

- 40724 Hilden

- Deutschland

-

+49 (2103) 28097-0

+49 (2103) 28097-99 -

info@LHmachine.com

www.LHmachine.com

#1083-02478 · Bevel Gear Generator - Spiral

KLINGELNBERG - KNC 25 P - - 1997 -

Technical details

Tool spindle (D-axis) - workpiece spindle speed (infinitely) 60 to 350 r.p.m. Tool positioning axis (E-axis) - swivel range 0 to 360° - swivel speed max. 19.5°/s Workpiece spindle (B-axis) - mounting diameter outer cone (1: 4) 140 mm - standard internal cone (1:20) 99.218 mm - workpiece spindle speed max. 300 r.p.m. - workpiece spindle passage 90 mm Workpiece positioning axis (Y-axis) - travel 870 mm - speed max. 4.5 m/min Roller rotation axis (A-axis) - swivel range 315° - swivel speed max. 40°/s Axis intersection (Z-axis) - travel range max. +/- 50 mm - speed max. 0.657 m/min Workpiece swivel axis (C-axis) - swivel range -8.5 to 98° - swivel speed max. 21.5 °/s Milling depth axis (X-axis) - travel from -25 to 640 mm - max. speed 6 m/min Machinen distance (V-axis) - travel 150 mm - speed max. 1.6 m/min - 13 milling cutters included -

36.000 €

Datasheet

Request / Contact

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

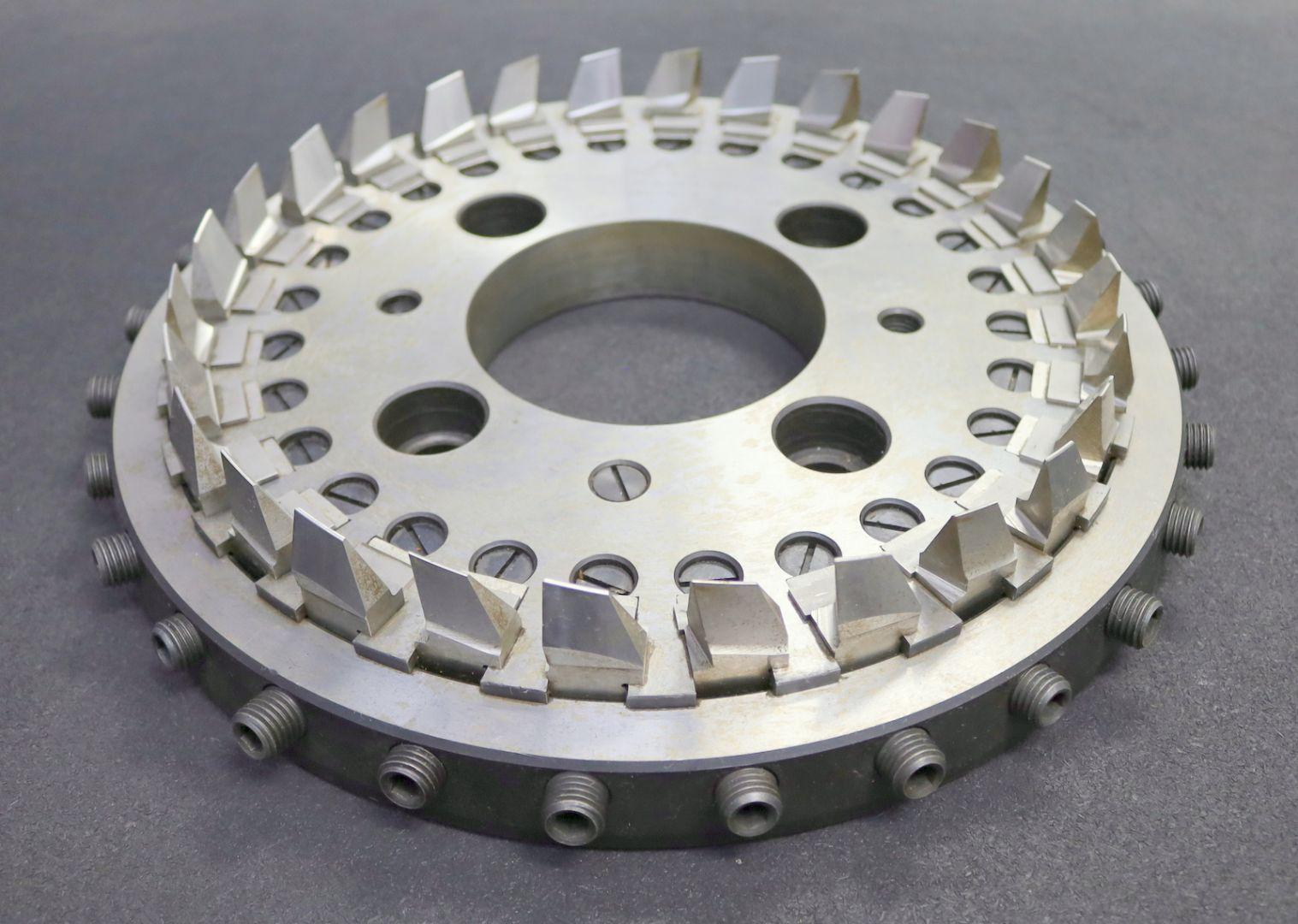

#1139-00446 · Bevel Gear Generator - Spiral

WMW-MODUL - MK 12 - - - konventionell

Technical details

WMW MODULE Arcoid cutter head MK 12" 2§m - 304.8 for bevel gears with tapered tooth height analog Gleason for bevel gear milling machine MODUL ZFTKK 500 28 knife inserts 05M VESTA WORKS 552 A-311 AJ/ck 30499005 used weight 29.4kg We have 4 different types in stock. You can come and inspect the article at our warehouse in Giebelstadt about 80min. from FRANKFURT AIRPORT.

Double Flank Gear Testing Machine

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23151 · Double Flank Gear Testing Machine

MAHR - 898 C - - 1990 -

Technical details

- Universal gear testing machine 898 C Determination of the rolling deviation, the rolling contact gap and the circumferential backlash on externally and internally toothed pinions with straight and helical teeth, as well as on bevel and worm gears. - Testing of individual deviations - concentricity deviation and tooth thickness variations on cylindrical gears, bevel gears and worm gears. Technical data: - Adjustable centre distance Between centres 25 - 300 mm Flying support 25 - 550 mm - Maximum permissible wheel weight On the adjusting slide 250 kg On the measuring slide 100 kg - With abutment 898 CD-w4 Centre distance On the measuring slide 50 - 750 mm Throat 140 mm min. Centre distance 65 mm Accessories: - Base cabinet 898 C-us - Feed slide 898 CD-S2 - Electrical equipment 898 CD-e - abutment 898 CD-w4 (centre distance 150-750 mm) - electronic precision indicator "Millitron

Datasheet

Request / Contact

TOP Manufacturer:

MAHR -