Chamfering and Deburring Machine

Machinelist: Chamfering and Deburring Machine

Bevel Gear Grinding Machine

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17944 · Bevel Gear Grinding Machine

GLEASON - Phoenix 275 G - - 2008 - SIN 840 D SIEMENS

Technical details

Hoffmann coolant filter system ERK 140-V(L-C) (built 2008) VT oil mist filter system

Datasheet

Request / Contact

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17513 · Bevel Gear Grinding Machine

GLEASON - Phoenix 275 G - - 2007 - 160 i - MB FANUC

Technical details

WAGURI with EWAB robot cell (KUKA Robot) no coolant filter system available

Datasheet

Request / Contact

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17512 · Bevel Gear Grinding Machine

GLEASON - Phoenix 275 G - - 2005 - SIN 840 D SIEMENS

Technical details

WAGURI with EWAB load cell built in 2012 (Linear loader) no coolant filter system available

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

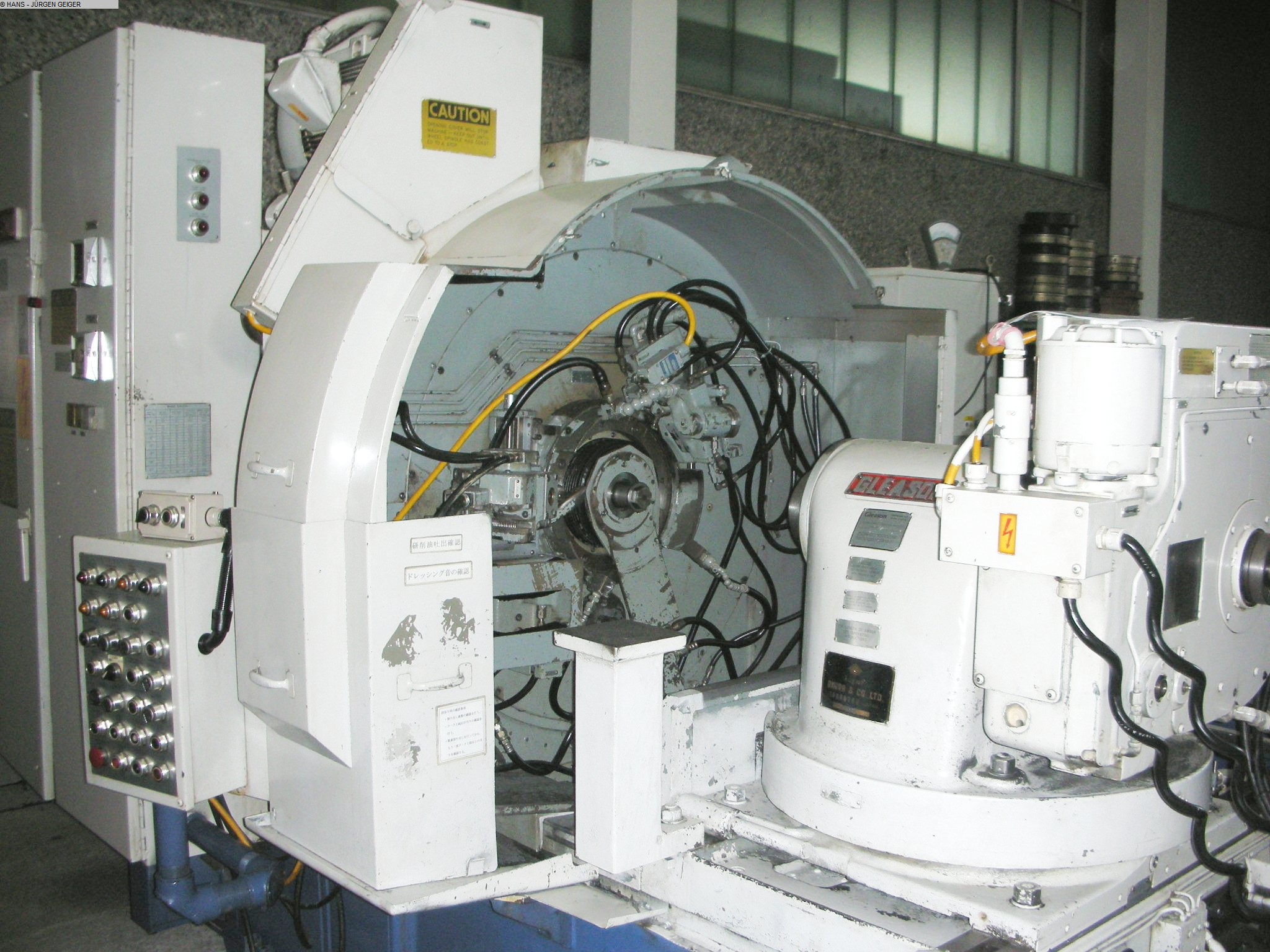

#1049-328540 · Bevel Gear Grinding Machine

GLEASON - PHOENIX 200 HG - - 1997 -

Technical details

Max. external Ø of workpiece 215 mm Tooth profile, height x width 16 x 40.65 mm No. of teeth 5 - 200 Max. tooth ratio 1 : 10 Grinding wheel Ø 51 - 190 mm Grinding wheel speeds 1,000 - 6,000 rpm X Axis (horizontal) 152 mm Y Axis (vertical) 178 mm Z Axis (slide base plate) 304 mm Distance from middle of machine to middle of workspindle 115 mm Axial speed 125 mm/sec Workpiece speeds 0 - 30 rpm Workspindle bore, conical 3 29/32 inch Total electrical load 20 kW - 380 V - 50 Hz Weight, approx. 10,000 kg Accessories / Special Features * FANUC CNC Control, Model 150 MB, for 7 axes, with monitor and direct input. Automatic calculation of all workpiece and grinding parameters. * Extensive coolant equipment with filter system, band filter, etc. * Driven grinding wheel dressing device with CNC dressing control for automatic compensation of form and diameter after every dressing. * Gear grinding is effected either in single component operation using a conical cup wheel (Gleason 30°), or with a cylindrical cup wheel. These grinding wheels can be made of CBN, or of traditional "dressable" aluminium oxide material (question of cost). Grinding with a conical grinding wheel is of advantage with regard to heat build-up and quality of tooth contact pattern. Therefore these pairs of bevel gears (for automotive industry) can be generated in high quality with consistent accuracy, economically, and with short set-up times. Condition : Very good - machine can be inspected here under power Delivery : Ex stock, as inspected Payment : Net, after conclusion of contract Thank you for your interest. We always have a good selection of gear machines available. Please let us know what you need.

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-304112 · Bevel Gear Grinding Machine

GLEASON - 120 / 888 W - - 1980 -

Technical details

Max. depth of tooth 10 mm Max. workpiece Ø (for clearance) 1,010 mm Max. external Ø of coupling 610 mm Sliding base withdraw 216 mm Max. distance from grinding wheel to workpiece nose 90 - 430 mm Max. weight of workpiece, including clamp 500 kg No. of teeth 32 to 150 Grinding wheel Ø, approx 152 - 320 mm Grinding wheel speeds, infinitely variable 0 - 3,600 rpm Work spindle bore 60 mm Total electrical load, approx. 15 kW - 380 V - 50 Hz Weight, approx. 9,500 kg Accessories / Special Features * Automatic roughing and finishing process via pre-settable counter and built-in feed cam. * Counter for number of teeth. * Counter for number of dressing cycles. * 2 built-on dressing units with three dressing diamonds for radius dressing, side dressing and wheel end dressing. * Built-on index plate for 48 teeth. * Separate coolant device with band filter. * Separate hydraulic unit. * Separate TRION oil mist exhaust. * Various small parts.

Chamfering and Deburring Machine

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-341998b · Chamfering and Deburring Machine

HURTH - ZK 200/1-TE CNC - - 1991 -

Technical details

CNC controlled milling machine for synchronous rings

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-347971 · Chamfering and Deburring Machine

PRÄWEMA - W 2 - 1 SYNCHROFORM - - 1991 -

Technical details

Workpiece Ø, min./max. 30 - 400 mm Number of teeth 6 - 150 Module range, max. 5 Tool holder shaft Ø SK 30 / 20 Tool speeds 4,000 rpm Spindle drive max. infinitely variable 1.8 kW Feeds, longitudinal and cross 0.001 - 12 m/min Workpiece speed, max. (1.5 kW) C Axis 2,000 rpm Workspindle slide 400 mm Tool speed, max. 3,000 rpm Tool holder SK 30 Total electrical load, approx. 16 kW - 380 V - 50 Hz Weight, approx. 10,000 kg Accessories / Special Features * BWO (HECKLER & KOCH) CNC Control model 785 H for altogether 7 axes. Input via monitor. The control has all the supervision and fault diagnosis features necessary for fully automatic working process. * 2 workspindle units, left and right, which can be set at any angle. * CNC controlled: Z and W Axes for tool cross slide. X and U Axes for tool longitudinal slide. * L and O Axes for milling spindle. C Axis for workspindle rotation. * Manually controlled: Tool slide rotary table (B and E Axes). Tool slide vertical infeed (V and Y Axes). Tilt of tool head (A and D Axes). All axes have digital display in the control. * Hydraulically operated workpiece clamping device in conjunction with an automatic loading device using workpiece feed / conveyor belt and swivelling loading device, as well workpiece control by air. * Coolant equipment with chip conveyor. * Noise protection cabin. * Central lubrication. * Built-on hydraulic unit. * Pneumatically driven safety doors. * Deburring device, etc. The machine uses the hypocycloidal milling principal, with electronically synchronized tool and workpiece axes for working straight roof-formed teeth, symmetric as well as asymmetric forms. Advantages are high precision and productivity. Condition : Good to very good. Machine can soon be inspected under power. Delivery : Ex stock, as inspected Payment : Net, after conclusion of contract Thank you for your interest. We always have a good selection of gear machines available on stock.

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com