Gear Deburring Machine

Machinelist: Gear Deburring Machine

Bevel Gear Grinding Machine

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17944 · Bevel Gear Grinding Machine

GLEASON - Phoenix 275 G - - 2008 - SIN 840 D SIEMENS

Technical details

Hoffmann coolant filter system ERK 140-V(L-C) (built 2008) VT oil mist filter system

Datasheet

Request / Contact

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17513 · Bevel Gear Grinding Machine

GLEASON - Phoenix 275 G - - 2007 - 160 i - MB FANUC

Technical details

WAGURI with EWAB robot cell (KUKA Robot) no coolant filter system available

Datasheet

Request / Contact

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17512 · Bevel Gear Grinding Machine

GLEASON - Phoenix 275 G - - 2005 - SIN 840 D SIEMENS

Technical details

WAGURI with EWAB load cell built in 2012 (Linear loader) no coolant filter system available

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

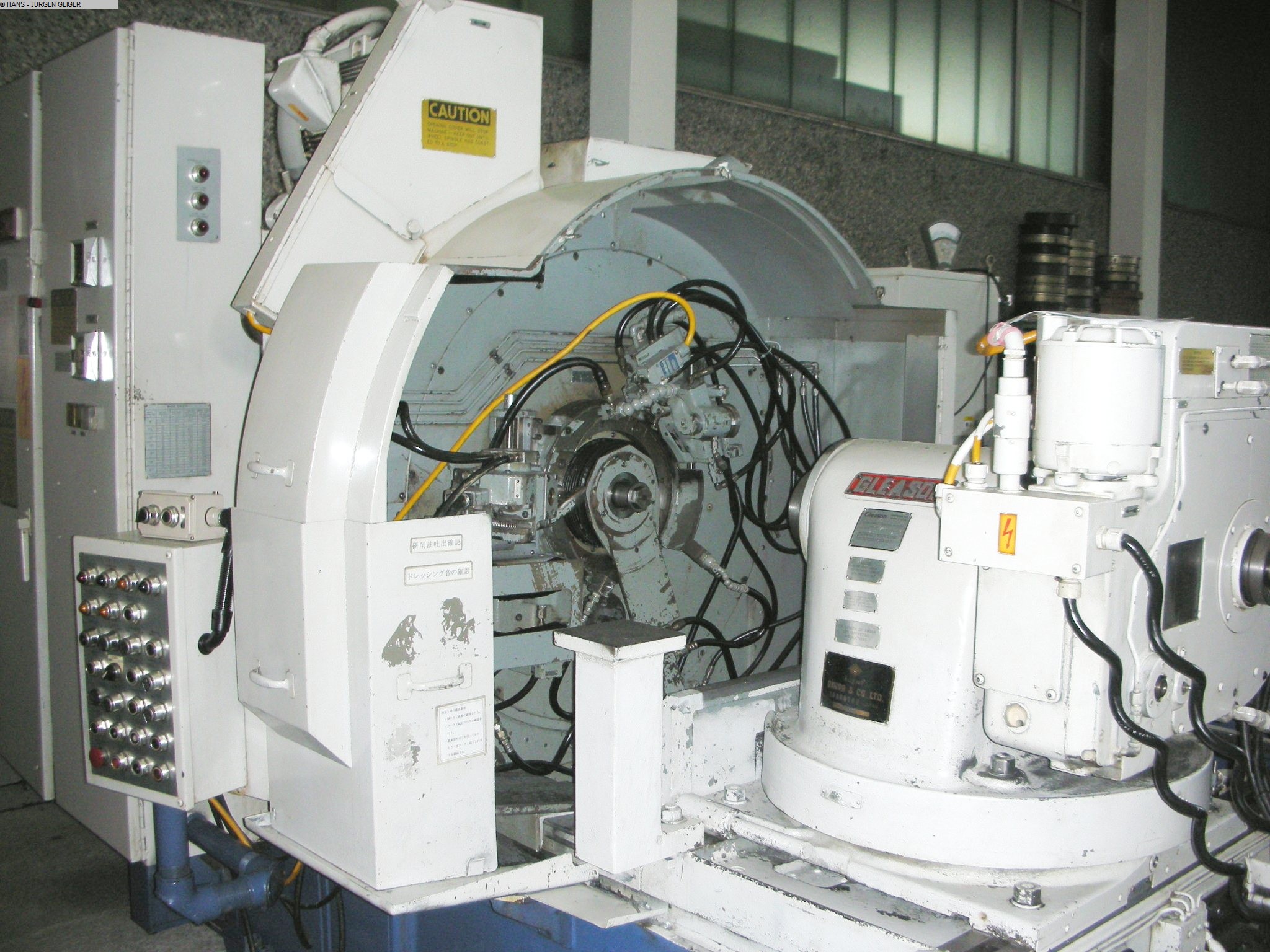

#1049-328540 · Bevel Gear Grinding Machine

GLEASON - PHOENIX 200 HG - - 1997 -

Technical details

Max. external Ø of workpiece 215 mm Tooth profile, height x width 16 x 40.65 mm No. of teeth 5 - 200 Max. tooth ratio 1 : 10 Grinding wheel Ø 51 - 190 mm Grinding wheel speeds 1,000 - 6,000 rpm X Axis (horizontal) 152 mm Y Axis (vertical) 178 mm Z Axis (slide base plate) 304 mm Distance from middle of machine to middle of workspindle 115 mm Axial speed 125 mm/sec Workpiece speeds 0 - 30 rpm Workspindle bore, conical 3 29/32 inch Total electrical load 20 kW - 380 V - 50 Hz Weight, approx. 10,000 kg Accessories / Special Features * FANUC CNC Control, Model 150 MB, for 7 axes, with monitor and direct input. Automatic calculation of all workpiece and grinding parameters. * Extensive coolant equipment with filter system, band filter, etc. * Driven grinding wheel dressing device with CNC dressing control for automatic compensation of form and diameter after every dressing. * Gear grinding is effected either in single component operation using a conical cup wheel (Gleason 30°), or with a cylindrical cup wheel. These grinding wheels can be made of CBN, or of traditional "dressable" aluminium oxide material (question of cost). Grinding with a conical grinding wheel is of advantage with regard to heat build-up and quality of tooth contact pattern. Therefore these pairs of bevel gears (for automotive industry) can be generated in high quality with consistent accuracy, economically, and with short set-up times. Condition : Very good - machine can be inspected here under power Delivery : Ex stock, as inspected Payment : Net, after conclusion of contract Thank you for your interest. We always have a good selection of gear machines available. Please let us know what you need.

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-304112 · Bevel Gear Grinding Machine

GLEASON - 120 / 888 W - - 1980 -

Technical details

Max. depth of tooth 10 mm Max. workpiece Ø (for clearance) 1,010 mm Max. external Ø of coupling 610 mm Sliding base withdraw 216 mm Max. distance from grinding wheel to workpiece nose 90 - 430 mm Max. weight of workpiece, including clamp 500 kg No. of teeth 32 to 150 Grinding wheel Ø, approx 152 - 320 mm Grinding wheel speeds, infinitely variable 0 - 3,600 rpm Work spindle bore 60 mm Total electrical load, approx. 15 kW - 380 V - 50 Hz Weight, approx. 9,500 kg Accessories / Special Features * Automatic roughing and finishing process via pre-settable counter and built-in feed cam. * Counter for number of teeth. * Counter for number of dressing cycles. * 2 built-on dressing units with three dressing diamonds for radius dressing, side dressing and wheel end dressing. * Built-on index plate for 48 teeth. * Separate coolant device with band filter. * Separate hydraulic unit. * Separate TRION oil mist exhaust. * Various small parts.

Gear Deburring Machine

- IMZ Maschinen Vertriebs GmbH

- Marie-Curie-Straße 19

- 73529 Schwäbisch Gmünd

- Deutschland

-

0049 (0) 7171 987130

0049 (0) 7171 9871329 -

info@imz.de

www.imz.de

#1075-7039 · Gear Deburring Machine

KLAASSEN - RZ 15 - - 2019 -

Technical details

6-axis industrial robot YASKAWA MH50 2 CNC rotary tables 1. rotary table 1 and rotary table 2 limited Nmax=1.300 1/min Reduction ratio I= 1:72 Nmax: Reduction ratio and Nmax motor corresponds to 120°/sec on the table Mdnenn. Output = 828 Nm Maximum centric loading weight = 15 kN Centering force from inside to outside clamping = 7,540 N @ 6 bar Centering accuracy in the gripper = 0.05 mm [PA] Rotary field restriction depending on cable and hose situation Provided for ± 720° (provide for this in the robot controller) Motor: YASKAWA SGMRV-20ANA-YR11 Milling spindle: AMTRU (CH), type Flexicut 250 Gearbox: ZAE Hamburg, type: S100B-1300/65-HOX-72.0:1-3000 Version: with Yaskawa servo axis + ZAE worm servo gearbox

Datasheet

Request / Contact

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de

#2052-06313 · Gear Deburring Machine

GLEASON HURTH - ZSE 160 T - - 2001 - Siemens Sinumeric

Technical details

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de

#2052-06297 · Gear Deburring Machine

GLEASON HURTH - ZSE 160T - - 2001 - SIEMENS SINUMERIC 840D

Technical details

Gear shaving - / deburring machine ++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ Please note: The machine is dismantled and ready for loading. It is not possible to show it under power or make a video. Our offer includes already the best pictures. So we don’t have and won’t send additional pictures. ++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de

#2052-06296 · Gear Deburring Machine

GLEASON HURTH - ZSE 160T - - 2001 - SIEMENS SINUMERIC 840D

Technical details

Gear shaving - / deburring machine ++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ Please note: The machine is dismantled and ready for loading. It is not possible to show it under power or make a video. Our offer includes already the best pictures. So we don’t have and won’t send additional pictures. ++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

- SK Maschinen-Service GmbH

- Tackweg 4

- 47918 Tönisvorst

- Deutschland

-

02151 79350

02151 793535 -

info@sk-maschinen.de

www.sk-maschinen.de

#1038-80393 · Gear Deburring Machine

RAUSCH-GRATOMAT - GRATOMAT 2000 - - 1963 -

Technical details

uncomplete machine body with drive motor. drive unit fully functional. Without grinding unit.